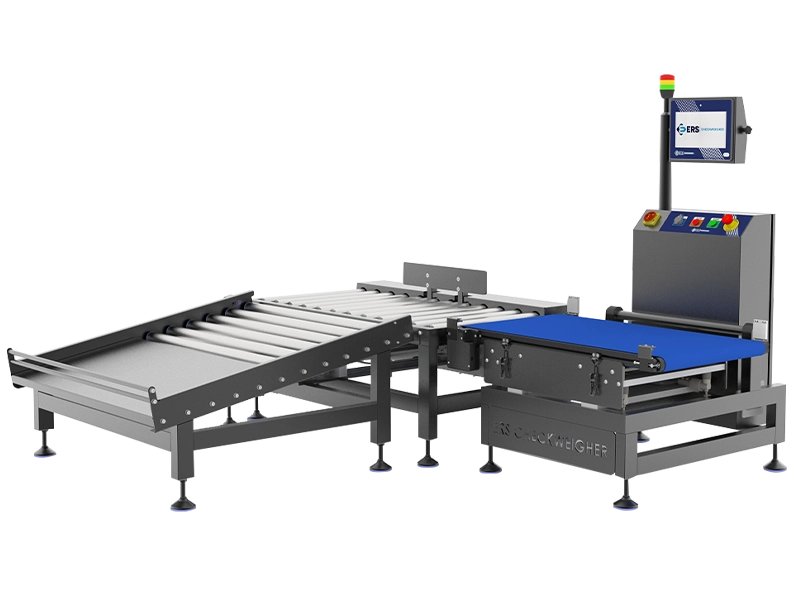

The shipping processes of textile and clothing products are not limited to sending the right product to the right address; at the same time, complete, consistent and standard-compliant packaging is also an important part of the process.he shipping processes of textile and clothing products are not limited to sending the right product to the right address; at the same time, complete, consistent and standard-compliant packaging is also an important part of the process. At this point, the weight control scales contribute to the safe and trouble-free execution of logistics operations by providing the correct content control in the packaging line.

The risk of missing items is quite high in packages that contain multiple components, such as multi-piece product groups, underwear sets, accessories or promotional packaging. Weight control systems instantly detect missing items by checking whether such sets have the specified totalhe risk of missing items is quite high in packages that contain multiple components, such as multi-piece product groups, underwear sets, accessories or promotional packaging. Weight control systems instantly detect missing items by checking whether such sets have the specified total weight. This both increases customer satisfaction and prevents refunds and complaints.

Weight control scales integrated into the packaging process work in tandem with production data to create a digital weight record for each package. This data can be integrated into warehouse management systems or ERP software. Thus, final checks before shipment are made digitally and traceability is provided in the logisticsight control scales integrated into the packaging process work in tandem with production data to create a digital weight record for each package. This data can be integrated into warehouse management systems or ERP software. Thus, final checks before shipment are made digitally and

The shipping processes of textile and clothing products are not limited to simply sending the right product to the right address; at the same time, complete, consistent in weight and compliant packaging is an important part of the process.he shipping processes of textile and clothing products are not limited to simply sending the right product to the right address; at the same time, complete, consistent in weight and compliant packaging is an important part of the process. At this point, the weight control scales contribute to the safe and trouble-free execution of logistics operations by providing the correct content control in the packaging line.

The risk of missing items is quite high in packages that contain multiple components, such as multi-piece product groups, underwear sets, accessories or promotional packaging. Weight control systems instantly detect missing items by checking whether such sets have the specified totalhe risk of missing items is quite high in packages that contain multiple components, such as multi-piece product groups, underwear sets, accessories or promotional packaging. Weight control systems instantly detect missing items by checking whether such sets have the specified total weight. This both increases customer satisfaction and prevents refunds and complaints.

Weight control scales integrated into the packaging process work in tandem with production data to create a digital weight record for each package. This data can be integrated into warehouse management systems or ERP software. Thus, final checks before shipment are made digitally and traceability is provided in the logisticsight control scales integrated into the packaging process work in tandem with production data to create a digital weight record for each package. This data can be integrated into warehouse management systems or ERP software. Thus, final checks before shipment are made digitally and

Missing items in multi-piece packages are detected immediately.

Every product is packaged with the correct weight and content specified.

Weighing data works integrated with ERP and warehouse systems.

Transport goods are optimized in the number of weight information.