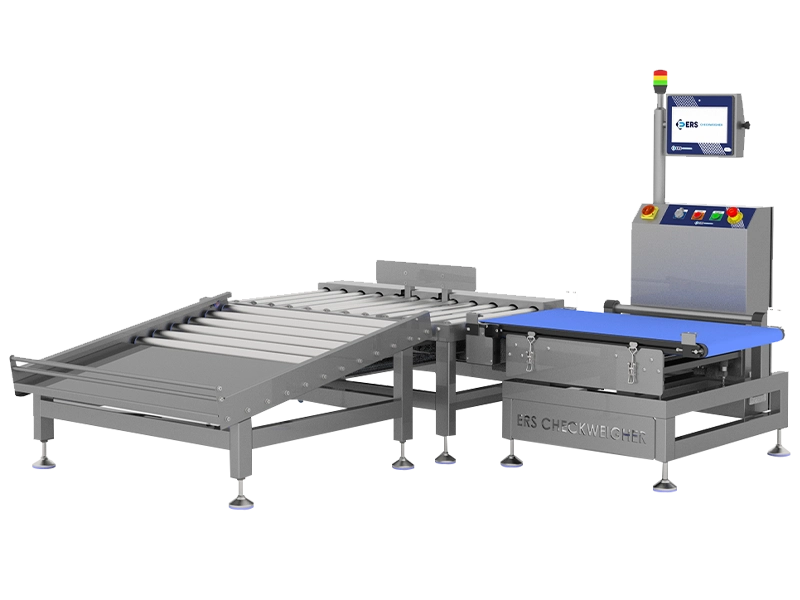

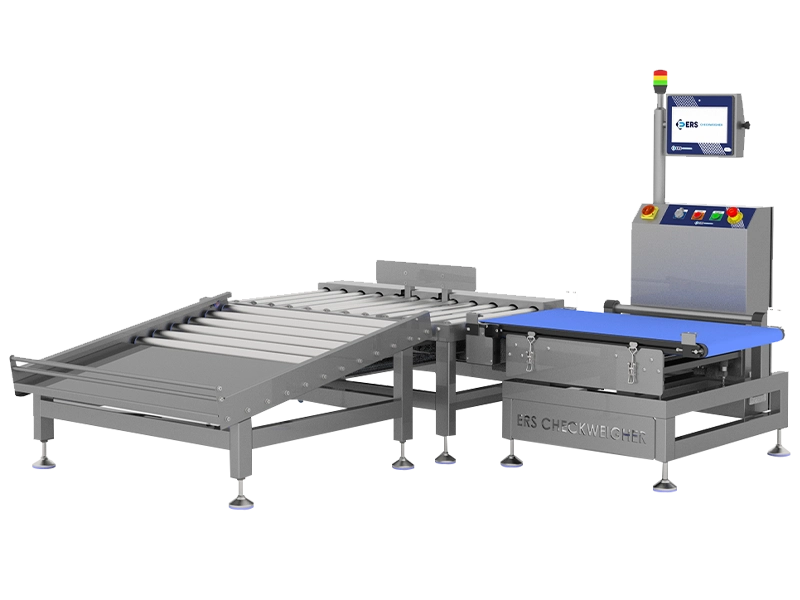

Production processes in the automotive industry are based on high speed, low tolerance and full reproducibility. Therefore, it is essential to control every step from part production to assembly and to maintain the standard. Weight control scales stand out as an important quality control tool in thisroduction processes in the automotive industry are based on high speed, low tolerance and full reproducibility. Therefore, it is essential to control every step from part production to assembly and to maintain the standard. Weight control scales stand out as an important quality control tool in this process. The fact that the weight of each part complies with the specified specifications directly affects both assembly compatibility and safety standards.

In the production of sensitive components such as engine parts, braking systems, steering mechanisms and electronic components, the use of missing or excessive materials can negatively affect the performance of the parts. Thanks to the weight control systems, each product is measured at the milligram level on the production line and checked whether it is within the targeted December.n the production of sensitive components such as engine parts, braking systems, steering mechanisms and electronic components, the use of missing or excessive materials can negatively affect the performance of the parts. Thanks to the weight control systems, each product is measured at the milligram level on the production line and checked whether it is within the targeted December. Parts that go beyond the specified limits are automatically separated by the system and directed for re-evaluation.

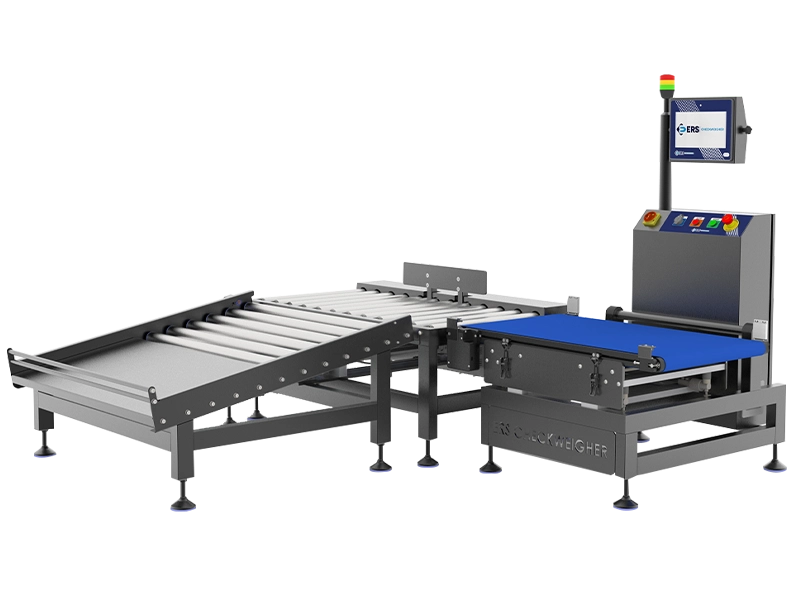

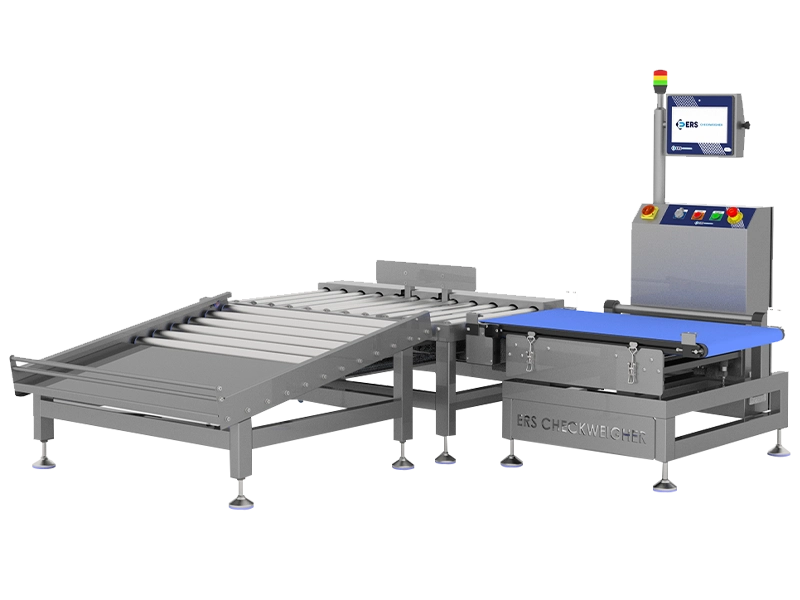

These systems also work in a way that is suitable for assembly line integrations. Scales that can move in synchronization with robotic lines can measure with high accuracy without reducing the production speedstems also work in a way that is suitable for assembly line integrations. Scales that can move in synchronization with robotic lines can measure with high accuracy without reducing the production speed. At the same time, it provides digital data recording for quality control teams, making it possible to analyze which product was produced when and in what way. This provides a significant advantage to companies, especially in the strict inspection processes in the automotive sector.

Another benefit of weight control is the reduction of error-related costs. When a faulty part reaches the assembly stage, it can affect the efficiency not only of that product but also of the entire assembly line. Thanks to weight control, faulty parts are detected at the production stage and possible stoppages are prevented

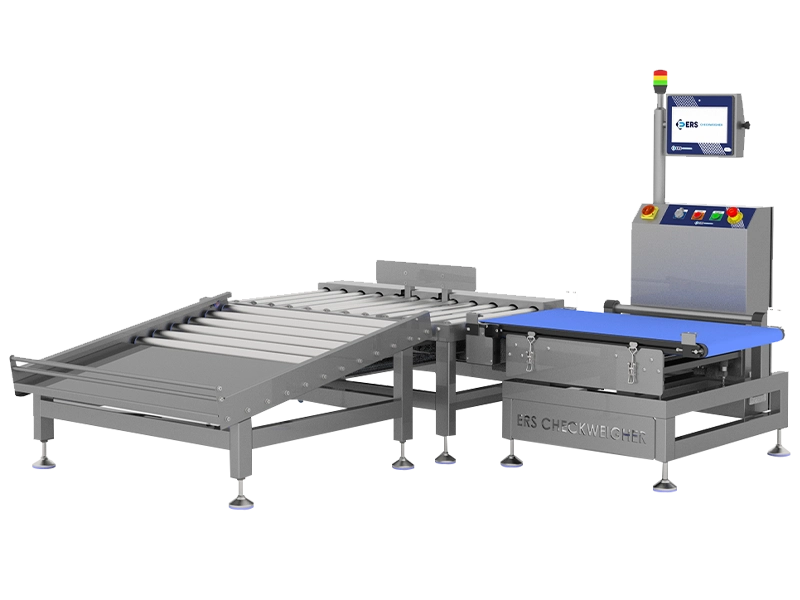

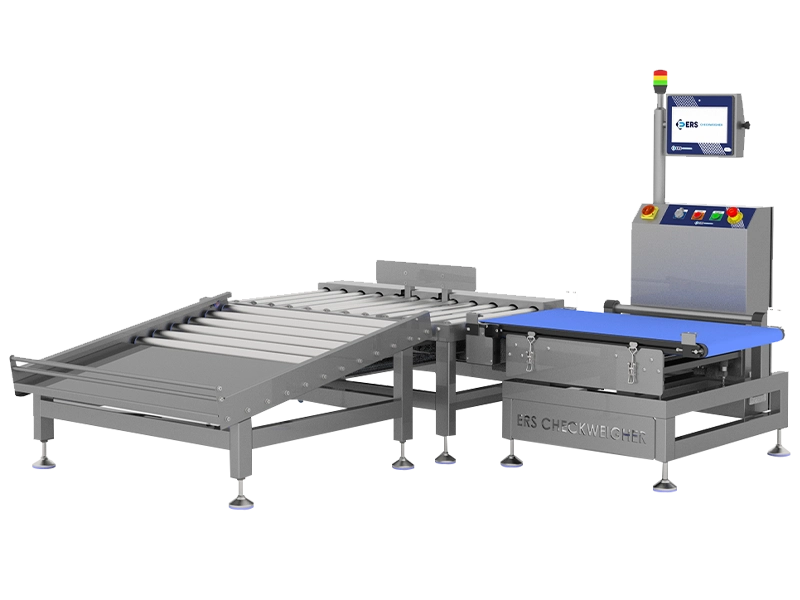

In the automotive spare parts sector, packaging is not only the packaging of a product; it is also the assurance that the right product reaches the end user in the right quantity and in the right way. Weight control scales ensure content accuracy and increase product safety in this arean the automotive spare parts sector, packaging is not only the packaging of a product; it is also the assurance that the right product reaches the end user in the right quantity and in the right way. Weight control scales ensure content accuracy and increase product safety in this area. Especially in the packaging of multi-part kits, fasteners or accessory groups, accurate weighing significantly reduces error rates.

In spare parts production, it is critical that the weight of parts such as screws, washers, circlips or sensors in the same package are consistent, both for the assembly process to proceed correctly and for there to be no deficiencies on the customer’s side.n spare parts production, it is critical that the weight of parts such as screws, washers, circlips or sensors in the same package are consistent, both for the assembly process to proceed correctly and for there to be no deficiencies on the customer’s side. Thanks to the weight control systems, these multiple components are quickly weighed on the production line and the missing or excess contents are detected instantly.

These systems not only perform weighing; they also digitally generate weight data for each package. These data can be integrated into barcode systems or ERP software. Thus, it is possible to obtain accurate information about the product’s history in any refund, complaint or warranty request.hese systems not only perform weighing; they also digitally generate weight data for each package. These data can be integrated into barcode systems or ERP software. Thus, it is possible to obtain accurate information about the product’s history in any refund, complaint or warranty request. Traceability is of great importance in contract manufacturing, especially for OEM (original equipment manufacturer) suppliers.

Weight control systems also prevent operator-related errors. Errors that can be made by manual counting or visual control can lead to serious time and resource losses, especially in high-quantity part groupseight control systems also prevent operator-related errors. Errors that can be made by manual counting or visual control can lead to serious time and resource losses, especially in high-quantity part groups. Thanks to the fully automatic weighing systems, these risks are minimized and continuity is ensured in the production line.

In addition, in order for parts produced in different sizes and materials to be processed on the same line, the systems must have a flexible structure and adjustable parameters. This allows for rapid switching between different part types

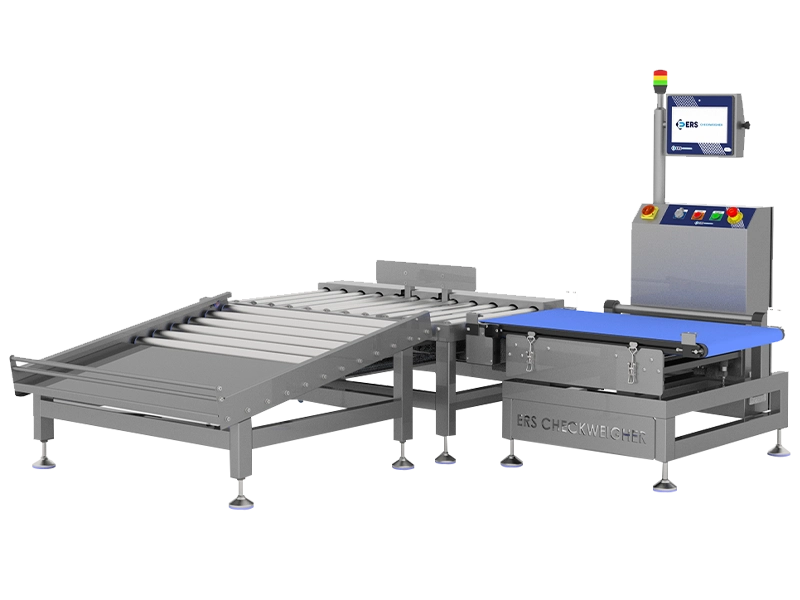

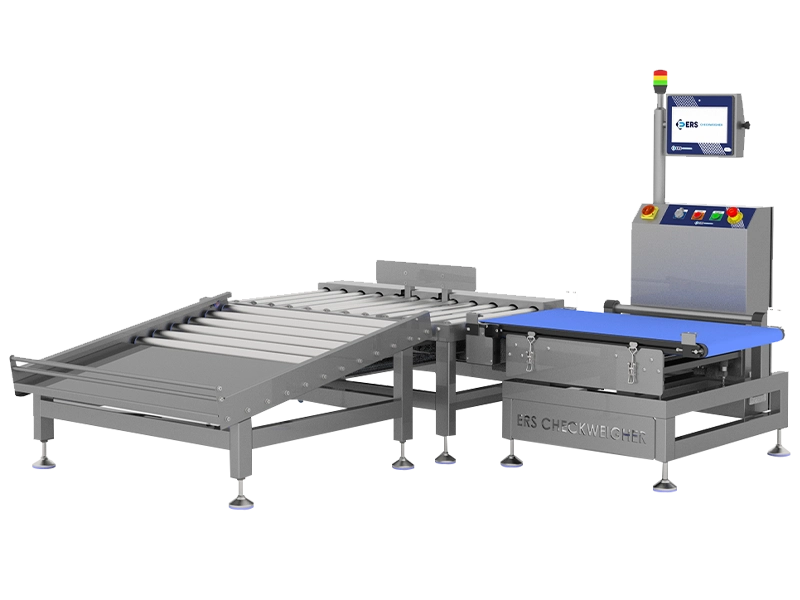

It provides accurate and precise weighing of chemical products.

It offers the same sensitivity on different types of products.

It is leak-proof, easy to clean and has a durable structure.

It meets the legal requirements and maintains customer trust.