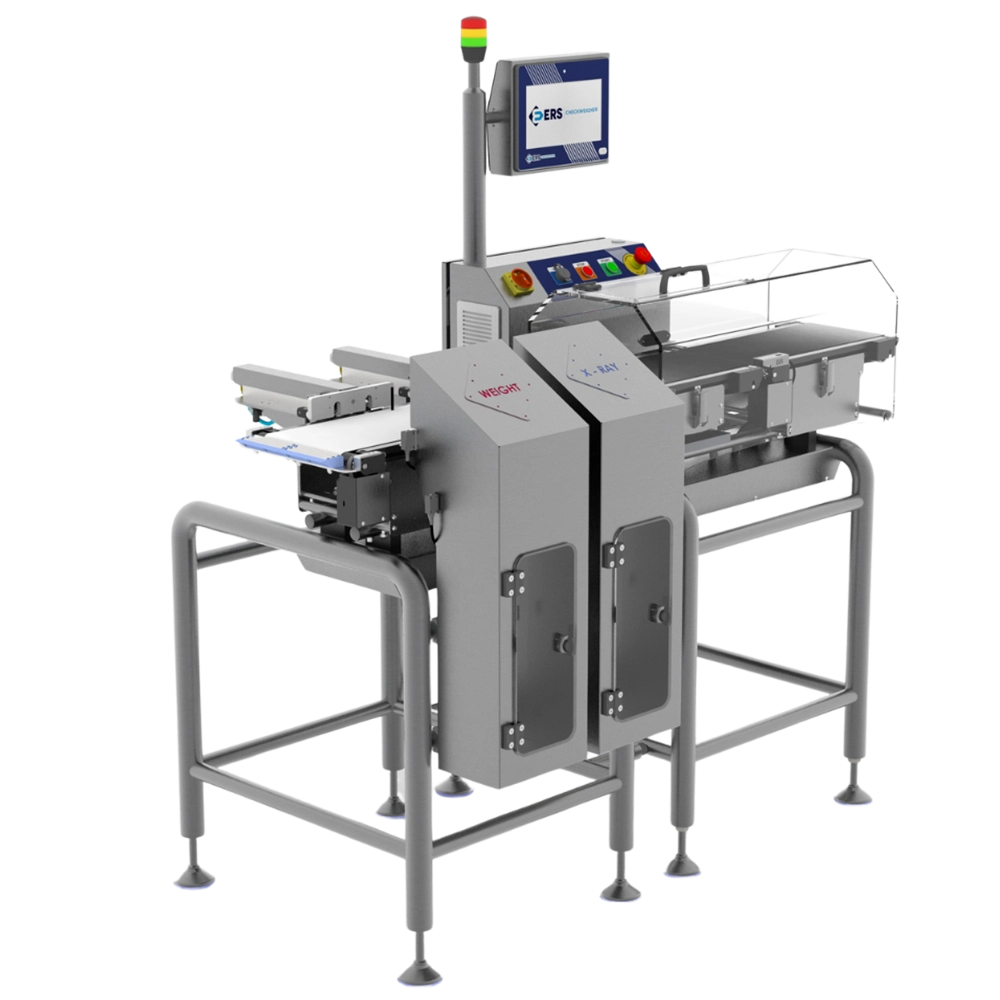

The automatic weight labeling system is one of the most critical functions that provides speed, accuracy and efficiency in modern production lines. The Weight Checking Scale Package Type 600 Gr model makes the packaging process more reliable and uninterrupted with this featurehe automatic weight labeling system is one of the most critical functions that provides speed, accuracy and efficiency in modern production lines. The Weight Checking Scale Package Type 600 Gr model makes the packaging process more reliable and uninterrupted with this feature. The automatic measurement and subsequent labeling of products according to the determined weight values contributes to both the maintenance of quality standards and the reduction of labor costs. Thanks to this system, operators do not need to deal with manual labeling operations. Since the process is completely automated, the risk of human error is eliminated.

Hygiene and accuracy are of great importance, especially in the food sector. Thanks to automatic labeling,

each package is prepared in accordance with the same standards and presented to the consumer safely. While this strengthens the reputation of the brands, it also increases customer satisfaction to the highest level.ygiene and accuracy are of great importance, especially in the food sector. Thanks to automatic labeling, each package is prepared in accordance with the same standards and presented to the consumer safely. While this strengthens the reputation of the brands, it also increases customer satisfaction to the highest level. In addition, the error-free application of labels also guarantees the compliance of products with legal regulations. Accurate and readable weight information both facilitates the audit processes and reflects the professionalism of the brand.

Automatic labeling systems also increase the production speed. Even seconds are important in the packaging line, and thanks to the speed offered by the device, time loss is minimized in large-scale production. Especially in high-capacity production facilities, manual labeling of each product individually creates a large workload.utomatic labeling systems also increase the production speed. Even seconds are important in the packaging line, and thanks to the speed offered by the device, time loss is minimized in large-scale production. Especially in high-capacity production facilities, manual labeling of each product individually creates a large workload. Thanks to this technology, production times are shortened and total productivity increases.

Another important advantage is traceability. Measurement data of each product can be recorded with automatic weight labeling. Thus, it can be tracked which package is measured with which value during the production process. This, in addition to providing quick solutions to possible problems, gives companies the opportunity to report in detail.

As a result, automatic weight labeling is not only a speed-saving feature; it is also a comprehensive solution that provides quality control, legal compliance, hygiene, customer confidence and savings in production costs.s a result, automatic weight labeling is not only a speed-saving feature; it is also a comprehensive solution that provides qua

The most critical issue in weight measuring devices is the accuracy rate. The Weight Control Scale Package Type 600 Gr is equipped with extremely sensitive sensors, so it can detect even the smallest gram differences.he most critical issue in weight measuring devices is the accuracy rate. The Weight Control Scale Package Type 600 Gr is equipped with extremely sensitive sensors, so it can detect even the smallest gram differences. Especially in sectors where precision is of great importance, such as food, medicine, cosmetics and chemistry, this feature guarantees the quality of production. The high accuracy rate ensures the reduction of firms that may occur during production and reduces costs.

Packaging of products with the wrong weight can lead to both customer complaints and legal problems. The high precision offered by this scale helps to prepare each package with the correct weight. Thus, brands always offer products to consumers with the same standards.ackaging of products with the wrong weight can lead to both customer complaints and legal problems. The high precision offered by this scale helps to prepare each package with the correct weight. Thus, brands always offer products to consumers with the same standards. Accurate measurement strengthens customer trust and also increases the brand’s perception of quality.

The sensitivity offered by the device is not limited to only the production quality; it also supports the production speed. The ability to measure quickly and accurately provides a great advantage in high-paced production lines. Operators can manage the process quickly by trusting the measurement resultshe sensitivity offered by the device is not limited to only the production quality; it also supports the production speed. The ability to measure quickly and accurately provides a great advantage in high-paced production lines. Operators can manage the process quickly by trusting the measurement results. This saves time, especially in mass-producing factories.

The high accuracy rate also reduces waste. Putting in more products than necessary means unnecessary costs for businesses. Placing too few products negatively affects customer satisfaction. This device increases the sustainability of the production line by eliminating both risks.e high accuracy rate also reduces waste. Putting in more products than necessary means unnecessary costs for businesses. Placing too few products negatively affects customer satisfaction. T

The 10.2-inch color touch panel, which brings the user experience to the highest level, is one of the most remarkable features of the device. The large screen size allows you to clearly see the measurement results and device settings. The intuitive interface of the touch panel allows operators to easily manage the device.he 10.2-inch color touch panel, which brings the user experience to the highest level, is one of the most remarkable features of the device. The large screen size allows you to clearly see the measurement results and device settings. The intuitive interface of the touch panel allows operators to easily manage the device. This user-friendly structure reduces training times and makes it possible for the device to be used easily by everyone.

Thanks to the touch panel, all settings of the device can be made quickly. Measurement modes, reporting options and statistical data can be controlled from a single screen. The color display saves time in the production process as it provides easy reading of data.hanks to the touch panel, all settings of the device can be made quickly. Measurement modes, reporting options and statistical data can be controlled from a single screen. The color display saves time in the production process as it prhanks to the touch panel, all settings of the device can be made quickly. Measurement modes, reporting options and statistical data can be controlled from a single screen. The color display saves time in the production process as it provides easy reading of data. Especially on busy lines, this speed provides a great advantage.

Another important feature offered by the panel is the possibility of multi-viewing. The operator can see both weight values and statistical information at the same time. This makes the production process more efficient and controllable.

In addition, the durable structure of the touch screen allows it to be used safely in industrial environments. Being resistant to dust, moisture or impact, it provides a long-lasting use. addition, the durable structure of the touch screen allows it to be used safely in industrial environments. Being resistant to dust, moisture or impact, it provi

In modern production lines, data analysis is at least as important as production. The Weight Control Scale Package Type 600 Gr not only shows the measurement results, but also presents them in the form of statistical data and detailed graphs.n modern production lines, data analysis is at least as important as production. The Weight Control Scale Package Type 600 Gr not only shows the measurement results, but also presents them in the form of statistical data ann modern production lines, data analysis is at least as important as production. The Weight Control Scale Package Type 600 Gr not only shows the measurement results, but also presents them in the form of statistical data and detailed graphs. This feature makes it easier to monitor and analyze the production process.

Thanks to statistical data, which products are measured at which values are recorded. This provides a great advantage in terms of quality control. The detection of faulty productions provides important information for the prevention of the same problems in the future.

Graphical representations help operators to visually monitor production performance. Seeing understandable graphs instead of complex numbers allows you to analyze the process faster. In this way, productivity-enhancing decisions can be made.Graphical representations help operators to visually monitor production performance. Seeing understandable graphs instead of complex numbers allows you to analyze the process faster. In this way, productivity-enhancing decisions can be made.

The data reports provided by the device support both daily production monitoring and long-term planning. Thanks to these reports, managers can easily see which products have more waste, which hours of production are more efficient.

As a result, statistical data and graphs turn the Weight Checking Scale Package Type 600 Gr into an analysis tool that provides strategic advantage to businesses, rather than just a measuring device.

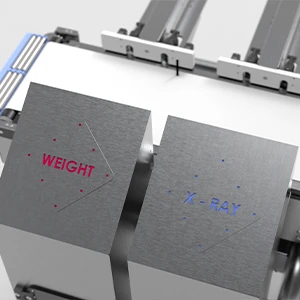

Different sizes and types of products can be processed on production lines. The Weight Checking Scale Package Type 600 Gr quickly adapts to this diversity thanks to its easy conveyor change featurerent sizes and types of products can be processed on production lines. The Weight Checking Scale Package Type 600 Gr quickly adapts to this diversity thanks to its easy conveyor change . The practicality of conveyor replifferent sizes and types of products can be processed on production lines. The Weight Checking Scale Package Type 600 Gr quickly adapts to this diversity thanks to its easy conveyor change feature. The practicality of conveyor replacement allows production processes to continue uninterruptedly.

This feature provides great convenience, especially for businesses that process different product groups on the same production line. The absence of long-term pauses during the conveyor change offers time and cost savings.

The easy exchange mechanism allows operators to manage the process without special training. Thanks to its simple and reliable design, the conveyor change is completed quickly and without errors.The easy exchange mechanism allows operators to manage the process without special training. Thanks to its simple and reliable design, the conveyor change is completed quickly and without errors.

This feature, which offThe easy exchange mechanism allows operators to manage the process without special training. Thanks to its simple a

Weight Control Scale Package Type 600 Gr is made in accordance with international standards with multiple language options. The device can be used in different countries and allows operators to manage in their own language. This feature is a great advantage, especially for businesses that produce for exportontrol Scale Package Type 600 Gr is made in accordance with international standards with multiple language options. The device can be used in different countries and allows operators to manage in their own language. This feature is a great advantage, especially for businesses that produce for export.

Multi-language support also contributes to reducing operator errors. Eliminating the language barrier allows the device to be used more efficiently.

In addition, the fact that the menus of the device can be presented in different languages reduces the training time on production lines where there are foreign employees. This increases labor productivity.

As a result, multi-language options make the device a global solution, not just a local one.

The intelligent automatic reset feature ensures that the device always gives the most accurate results. Thanks to this feature, the measurement accuracy of the scale is constantly maintained. The device resets itself at regular intervals without the need for user intervention and continues to makeThe intelligent automatic feature ensures that the device always gives the most accurate results. Thanks to this feature, the measurement accuracy of the scale is constantly maintained. The device resets itself at regular intervals without the need for user intervention and continues to make accurate measurements.

Continuous accuracy is of great importance in production lines. Automatic reset eliminates any deviations that may occur in the measurement, providing reliable results.

This feature reduces the workload of operators, especially in intensive production facilities. Since the device is self-controlled, users do not need to perform extra operations.

As a result, intelligent automatic resetting guarantees both accuracy and increases efficiency in the production process.