IP 65 Dust and Water Protection Sound and Light Alert

Product-based rejection systems

Locked Rejection Box

LAN Connection with PC

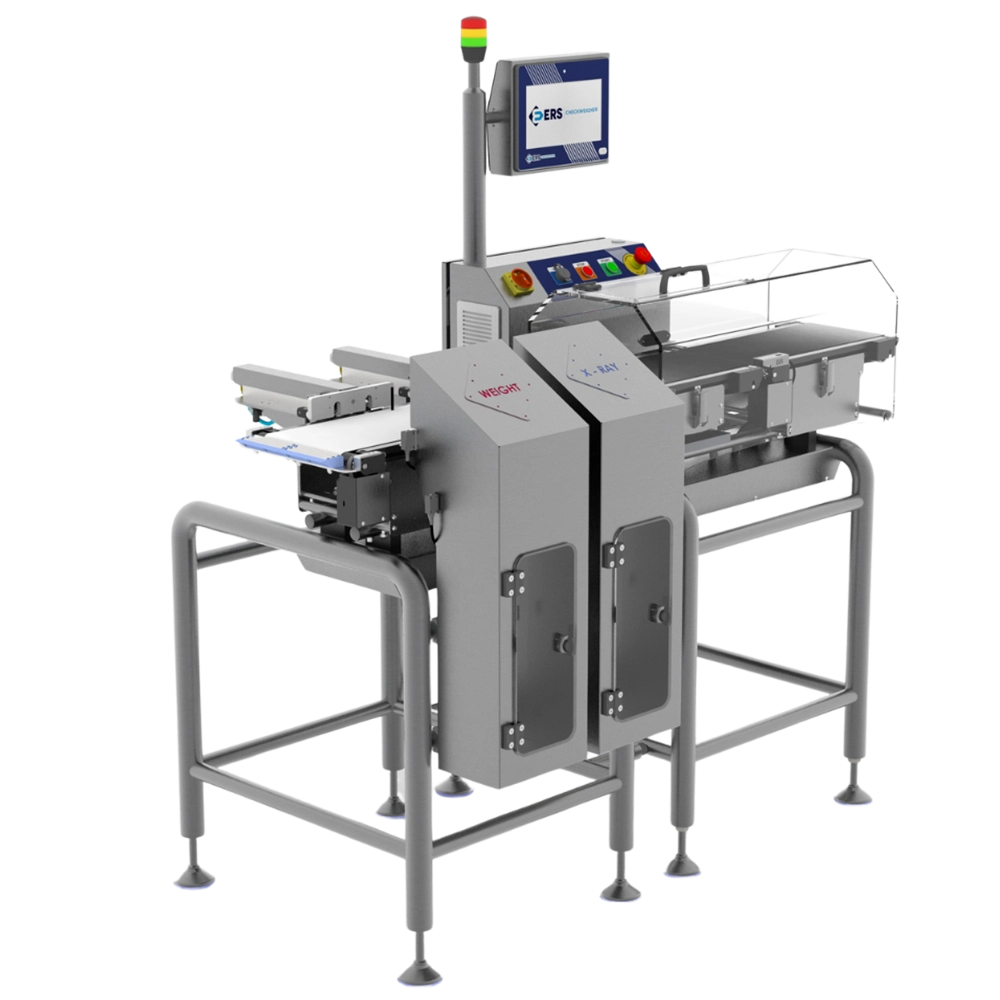

The metal detector is equipped with automatic weight labeling feature to ensure safe and error-free output of products on the production line. This system offers great advantages especially in the production processes of packaged food and sensitivehe metal detector is equipped with automatic weight labeling feature to ensure safe and error-free output of products on the production line. This system offers great advantages especially in the production processes of packaged food and sensitive products. As the products pass through the detector, the device both checks the metal and automatically transmits the weight value to the labeling system. This ensures that every package is weighed safely and correctly.

The automatic labeling system recognizes products of different sizes and grammars and equips them with the correct weight label. This feature minimizes operator intervention in the production line and prevents human errorshe automatic labeling system recognizes products of different sizes and grammars and equips them with the correct weight label. This feature minimizes operator intervention in the production line and prevents human errors. Especially on fast production lines, manual weighing and labeling can cause both time loss and faulty product output. The automatic weight labeling system, which works integrated with the metal detector, eliminates these risks.

The software of the device records the weight data of each package and integrates it into the quality control system. This ensures the traceability of all products on the production line and allows for the rapid detection of possible errors.he software of the device records the weight data of each package and integrates it into the quality control system. This ensures the traceability of all products on the production line and allows for the rapid detection of possible errors. Operators and managers can instantly see which product is having problems in weighing or metal detection and make the necessary intervention.

In addition, automatic labeling ensures that products are labeled accurately and aligned. This is critical for both regulatory standards and consumer confidence. The metal detector and automatic labeling system work together to make the production line both safe and efficient addition, automatic labeling ensures that products are labeled accurately and aligned. This is critical for both regulatory standards and consumer confidence. The metal detector and automatic labeling system work together to make the production line

The metal detector offers high sensitivity and accuracy to ensure product safety and quality in the production line. The device can detect possible metal contamination in packaged food, pharmaceuticals and sensitive products at the smallest particle sizehe metal detector offers high sensitivity and accuracy to ensure product safety and quality in the production line. The device can detect possible metal contamination in packaged food, pharmaceuticals and sensitive products at the smallest particle size. This feature is of critical importance both in terms of protecting consumer health and ensuring the quality standards of the production facility.

The device’s sensors are extremely sensitive in detecting metal and operate with high accuracy. Every product passing through the production line is automatically scanned and products containing metal are detected and separated from the production line immediately. In this way, the packaging and distribution of faulty or contaminated products is preventedhe device’s sensors are extremely sensitive in detecting metal and operate with high accuracy. Every product passing through the production line is automatically scanned and products containing metal are detected and separated from the production line immediately. In this way, the packaging and distribution of faulty or contaminated products is prevented. Precision, especially by enabling the detection of even small pieces of metal, maximizes production safety.

The accuracy feature minimizes the device from giving false positive or negative results. Operators can work more efficiently on the production line because they know that the measurement results are reliable. At the same time, the device supports quality control processes by recording production data and allows for quick reporting of possible faulty products.

This feature provides a critical advantage in large production facilities. Performing manual checks on busy production lines leads to both time loss and operator fatigue. The metal detector increases production efficiency by performing error-free and fast scanning with high sensitivity and accuracyhis feature provides a critical advantage in large production facilities. Performing manual checks on busy production lines leads to both time loss and operator fatigue. The metal detector increases production efficiency by performing error-free and fast scanning with high sensitivity and accuracy. The waste rate is reduced to a minimum and quality standards are maintained.

As a result, the high sensitivity and accuracy of the metal detector ensures safety, quality and efficiency in the production line. It detects all risks, from small metal particles to large metal contaminations, and guarantees that the production process proceeds without errorss a result, the high sensitivity and accuracy of the metal detector ensures safety, quality and efficiency in the production

The metal detector offers easy and fast control on the production line with its user-friendly 10.2 inch color touch panel. The large screen clearly visualizes metal detection results, scanning sensitivity, production statistics and system alertshe metal detector offers easy and fast control on the production line with its user-friendly 10.2 inch color touch panel. The large screen clearly visualizes metal detection results, scanning sensitivity, production statistics and system alerts. The touch interface allows operators to quickly switch between menus and conveniently manage all the functions of the device Decently.

The panel serves not only as a data display, but also as the control center for the production line. Operators can adjust scanning sensitivity, select automatic reset modes and manage alarmshe panel serves not only as a data display, but also as the control center for the production line. Operators can adjust scanning sensitivity, select automatic reset modes and manage alarms. In this way, it is ensured that faulty products are detected quickly during production and instant interventions of operators become possible.

The panel, made durable by industrial design, is resistant to impacts, dust and moisture. The color screen makes data tracking easy even in low-light environments. Graphical and color indicators make production data intuitive for operators and ensure quick understanding of scan resultshe panel, made durable by industrial design, is resistant to impacts, dust and moisture. The color screen makes data tracking easy even in low-light environments. Graphical and color indicators make production data intuitive for operators and ensure quick understanding of scan results. This helps the workflow to continue without interruption, especially on busy production lines.

The panel also works integrated with production statistics and graphs. Scan results and metal detection data are displayed instantly, historical data can be analyzed and reports can be obtained quicklyhe panel also works integrated with production statistics and graphs. Scan results and metal detection data are displayed instantly, historical data can be analyzed and reports can be obtained quickly. This feature makes the device no longer just a security tool, but a strategic tool for production management and quality control.

As a result, the 10.2-inch color touch panel is one of the most powerful features of the device in terms of ease of use, data tracking and production control. Thanks to the panel, operators can manage the production line safely and quickly, and use all the functions of the device with maximum efficiency.s a result, the 10.2-inch color touch panel is one of the most powerful features of

The metal detector not only detects metal in the production line; it also provides the opportunity to follow the production process in detail with its statistical data and graphics feature. The device records metal contamination data, number of scans and sensitivity levels of the scanned productshe metal detector not only detects metal in the production line; it also provides the opportunity to follow the production process in detail with its statistical data and graphics feature. The device records metal contamination data, number of scans and sensitivity levels of the scanned products. These data can be displayed in graphs and tables that are understandable by operators and managers, and the performance of the production line can be easily analyzed.

Statistics supported by graphs allow production processes to be optimized. Information such as which shift has a higher risk of metal contamination, which product groups have more errors, or which scan settings have decreased productivity can be clearly seen.tatistics supported by graphs allow production processes to be optimized. Information such as which shift has a higher risk of metal contamination, which product groups have more errors, or which scan settings have decreased productivity can be clearly seen. In this way, production planning and quality control processes are improved and faulty products are prevented.

The device’s data recording system is ideal for long-term analysis and reporting. Historical scanning data can be stored and possible risks can be identified in advance by analyzing production trends. This saves costs while improving safety in production and prevents faulty products from reaching the market.he device’s data recording system is ideal for long-term analysis and reporting. Historical scanning data can be stored and possible risks can be identified in advance by analyzing production trends. This saves costs while improving safety in production and prevents faulty products from reaching the market. At the same time, it creates a reliable data source in audit processes.

Graphical data also provides great convenience for operators. When the scanning results are visualized instantaneously, metal-containing products are detected quickly and intervention can be made on the production line. This feature increases the efficiency of the production line and reduces waste rates.Graphical data also provides great convenience for operators. When the scanning results are visualized instantaneously, metal-containing products are detected quickly and intervention can be made on the production line. This feature increases the efficiency of the production line and reduces waste rates.

As a result, the

The metal detector is designed with the feature of easy conveyor change, which ensures trouble-free processing of products of different sizes and weights on the production line. It is of great importance that the conveyor can be easily removed and installed in order to scan the products quickly and safely during production.he metal detector is designed with the feature of easy conveyor change, which ensures trouble-free processing of products of different sizes and weights on the production line. It is of great importance that the conveyor can be easily removed and installed in order to scan the products quickly and safely during production. This feature ensures uninterrupted operation of the production line and minimizes the time loss of operators.

Thanks to the easy conveyor change, different product types can pass through the detector quickly. For example, large packaged food products and small packages can be scanned seamlessly on the same production line.hanks to the easy conveyor change, different product types can pass through the detector quickly. For example, large packaged food products and small packages can be scanned seamlessly on the same production line. Operators can easily change the conveyor mode via the panel, and the device automatically makes the necessary adjustments. This increases the flexibility of the production line and prevents downtime.

This feature also provides great advantages in maintenance and cleaning processes. Conveyor parts can be removed and cleaned quickly, thus maintaining hygiene standards and ensuring production safety. The risk of operators making mistakes during conveyor replacement is minimized and work safety is increased.

During the conveyor change, the device optimizes the scanning sensitivity and metal detection mode with automatic settings. In this way, every product on the production line is scanned correctly and incorrect product output is prevented.uring the conveyor change, the device optimizes the scanning sensitivity and metal detection mode with automatic settings. In this way, every product on the production line is scanned correctly and incorrect product output is prevented. Especially in busy production lines, fast and safe conveyor change directly affects production efficiency.

As a result, easy conveyor changeover is a critical feature of the metal detector that increases efficiency in the production line, reduces the workload of operators and supports hygiene and safety. In this way, different product types can be processed quickly and accurately, and the production line operates uninterruptedly and safely

The metal detector is designed with multiple language options for different production facilities and multinational teams. This feature allows operators to use the device in their own language, reducing training time and reducing the risk of incorrect settings.he metal detector is designed with multiple language options for different production facilities and multinational teams. This feature allows operators to use the device in their own language, reducing training time and reducing the risk of incorrect settings. Personnel from different countries can display the menus and warnings of the device in their own language, so that they can work flawlessly and quickly on the production line.

Multi-language support not only provides ease of use, but also improves safety and quality in the production process. The operator can make the metal detection settings correctly and fully understand the warning system of the device while managing the device in his own language.ulti-language support not only provides ease of use, but also improves safety and quality in the production process. The operator can make the metal detection settings correctly and fully understand the warning system of the device while managing the device in his own language. This minimizes operator errors, especially on busy production lines, and prevents faulty product output.

The device’s software allows you to quickly change different language options. Production managers can view the device’s menus and reports in any language they want, making the international audit and reporting processes easier. This makes it possible for the production facility to adapt to different Sundays and standards.

Multi-language options also increase flexibility on the production line. A single device can be used seamlessly by different operators and different regional production teams. Language support expands the use area of the device and allows operators to manage the device quickly and securely.ulti-language options also increase flexibility on the production line. A single device can be used seamlessly by different operators and different regional production teams. Language support expands the use area of the device and allows operators to manage the device quickly and securely.

The metal detector has an intelligent automatic reset feature to ensure continuous precision and safety in the production line. Thanks to this feature, the device automatically resets itself at regular intervals and minimizes measurement deviationshe metal detector has an intelligent automatic reset feature to ensure continuous precision and safety in the production line. Thanks to this feature, the device automatically resets itself at regular intervals and minimizes measurement deviations. Without the need for operator intervention, the device always performs accurate and reliable scanning, guarantees uninterrupted operation of the production line.

Intelligent automatic reset provides a critical advantage, especially in high-volume production lines. Sensors detect minor deviations in the scanning process in real time and the device automatically balances itselfntelligent automatic reset provides a critical advantage, especially in high-volume production lines. Sensors detect minor deviations in the scanning process in real time and the device automatically balances itself. In this way, false positive or negative results are minimized, the waste rate is reduced and the production quality is constantly maintained. Operators can work comfortably throughout the process because they know that the device is always working correctly.

This feature also facilitates maintenance and quality control processes. The device’s automatic reset system eliminates measurement deviations, ensuring that the recorded data is reliable. Managers and quality control teams can quickly identify faulty products and optimize processes by analyzing production datahis feature also facilitates maintenance and quality control processes. The device’s automatic reset system eliminates measurement deviations, ensuring that the recorded data is reliable. Managers and quality control teams can quickly identify faulty products and optimize processes by analyzing production data. This both increases production safety and reduces costs.

Automatic reset relieves the workload of operators and supports the efficient operation of the production line. Since it does not require human intervention, operators follow only warning and statistical data. In this way, the accuracy and precision of the device are always kept at a high level while the production line is running continuously.

As a result, the smart automatic reset feature of the metal detector ensures high precision, safety and efficiency in the production line. It guarantees that the device will make accurate measurements continuously, reduces the workload of operators and provides cost and time savings to businessess a result, the smart automatic reset feature of the metal detector ensures high precision, safet