The logistics sector is based on the sustainability of operations based on accurate and fast information flow. The control of the weights of the packaged products plays a critical role both in terms of transportation planning and cost calculations.he logistics sector is based on the sustainability of operations based on accurate and fast information flow. The control of the weights of the packaged products plays a critical role both in terms of transportation planning and cost calculations. Weight control scales detect the net weight of the product in logistics processes and provide error-free data generation at stages such as transportation, storage and pricing.

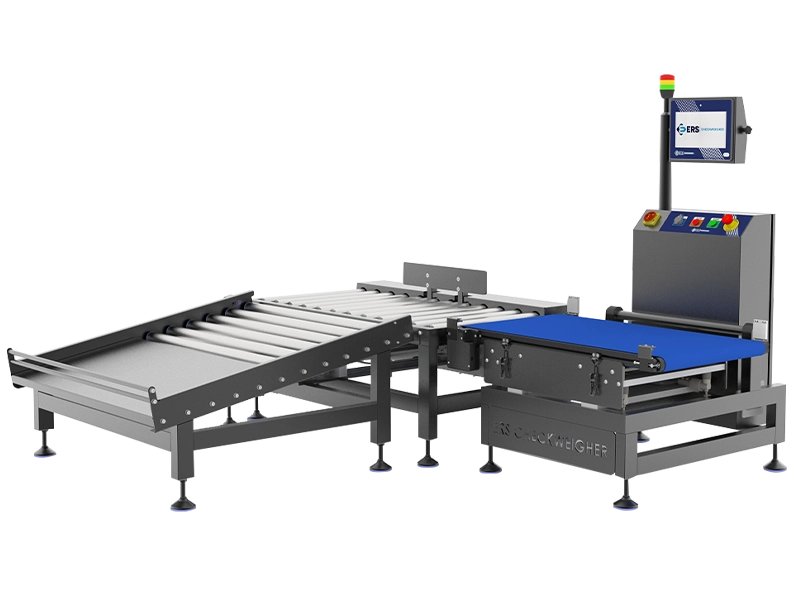

Each box or product leaving the warehouse is automatically measured by the weight control system integrated into the weighing belt. These systems instantly detect and separate packages with incorrect weights, preventing the processach box or product leaving the warehouse is automatically measured by the weight control system integrated into the weighing belt. These systems instantly detect and separate packages with incorrect weights, preventing the process from being disrupted. Thus, both incorrect loads are prevented and delays, returns or customer complaints that may occur during shipment are minimized.

In logistics, weight data usually works integrated into barcode or ERP systems. The weight control scales work in harmony with these software and generate digital data for each package. This increases both traceability and facilitates the recording of product movements.n logistics, weight data usually works integrated into barcode or ERP systems. The weight control scales work in harmony with these software and generate digital data for each package. This increases both traceability and facilitates the recording of product movements. Especially in fast-cycle logistics activities such as e-commerce, the automation and data accuracy provided by these systems provide a great advantage.

Loading plans and capacity calculations of transport vehicles also depend on accurate weight information. Missing or over-reported kilograms can directly affect transportation costs. In addition, in some countries, the difference between the declared weight and the actual weight at customs crossings may lead to serious sanctions. Dec.ing plans and capacity calculations of transport vehicles also depend on accurate weight information. Missing or over-reported kilograms can directly affe

In the packaging industry, each product must be prepared according to certain standards in terms of aesthetics, hygiene and content before reaching the end user. However, one of the most basic steps of this process is the packaging of the product in the target gram.n the packaging industry, each product must be prepared according to certain standards in terms of aesthetics, hygiene and content before reaching the end user. However, one of the most basic steps of this process is the packaging of the product in the target gram. Weight control scales are positioned as one of the most critical control tools of packaging lines at this point.

The products coming out of production are checked with automatic weighing systems before or after packaging. Products that are below or above the determined tolerance range are automatically separated byhe products coming out of production are checked with automatic weighing systems before or after packaging. Products that are below or above the determined tolerance range are automatically separated by the system. In this way, both customer satisfaction is ensured and situations such as product recall, complaint or refund are prevented.

Packaging lines may have different product types and weight targets. Therefore, weight control systems should have flexible adjustment options and be able to adapt to rapidackaging lines may have different product types and weight targets. Therefore, weight control systems should have flexible adjustment options and be able to adapt to rapid product changes. In addition, given the high speed on production lines, the ability of these systems to make accurate measurements in seconds directly affects the overall production performance.

Weight control in packaging lines in different sectors such as food, personal care, cleaning and consumer electronics is also subject to legal regulations. Especially with pre-packaged products, offering products below the specified net weight may lead to legal problems.eight control in packaging lines in different sectors such as food, personal care, cleaning and consumer electronics is also subject to legal regulations. Especially with pre-packaged products, offering products below the specified net weight may lead to legal problems. For this reason, it is of great importance for the system to make continuous and accurate measurements.

In addition, these scales contribute to quality control processes thanks to the data recording and analysis feature. Thanks to data such as production statistics, product-based error rates and fire analyses, companies can manage their processes more effectively. This means less waste, higher production accuracy and operational savings

Every product is packaged in the targeted weight and complete.

Out-of-tolerance products are eliminated by the system immediately.

It adapts quickly to different gramages and packaging.

Data is recorded automatically, making the quality process easier.