IP 65 Dust and Water Protection Sound and Light Warning

Ürün bazında reddetme sistemleri

Locked Rejection Box

LAN Connection with

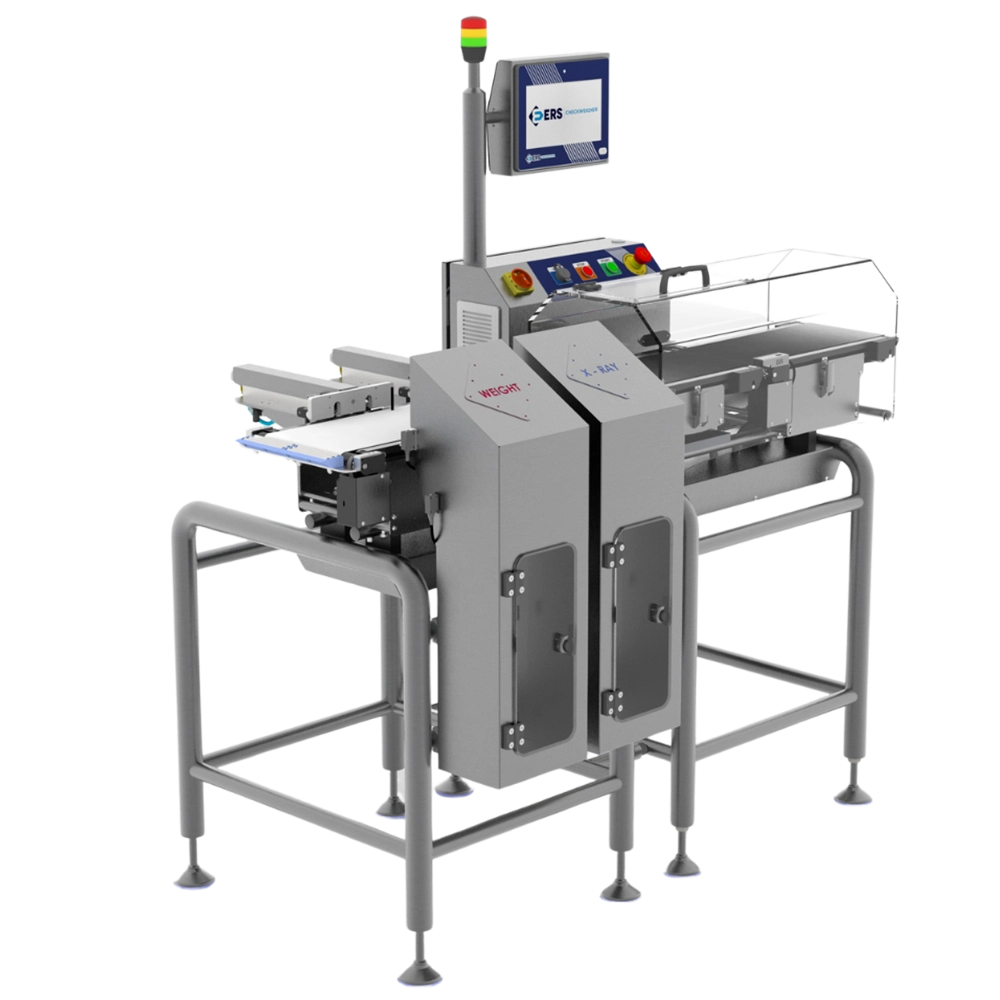

Accurately weighing and labeling each fish in fish processing facilities directly impacts production quality. The automatic weight labeling system weighs fish using precise sensors and instantly transmits the weight data to the labeling unit. This ensures that each package is marked with the correct weight, preventing incorrectly labeled products from causing problems during shipment.

The system is designed to operate without requiring operator intervention. Fish are processed quickly, regardless of size or weight. This automation prevents downtime on the production line and saves labor. Especially during busy production processes, operators can simply monitor the system’s correct operation and track data.

The automatic labeling system records production data, providing valuable information for analysis and reporting. Each fish’s weight data is stored in the system, and production trends and defective package rates can be tracked graphically. This allows quality control teams to quickly identify defective products and helps optimize the production process. Furthermore, labeling accuracy prevents defective packages in logistics and storage processes, improving shipping safety.

The system easily adapts to fish of different sizes and weights. Integrated with the conveyor, the automatic labeling unit ensures error-free measurement and labeling, even during high-speed production. This flexibility supports the efficient and uninterrupted operation of production lines in fish processing facilities. Operators simply monitor the process and intervene when necessary, significantly reducing workload.

In conclusion, the automatic weight labeling system is a critical technology that improves both quality and operational efficiency in fish processing. The system ensures smooth and error-free production line operation through accurate measurement, fast labeling, and reliable data recording.

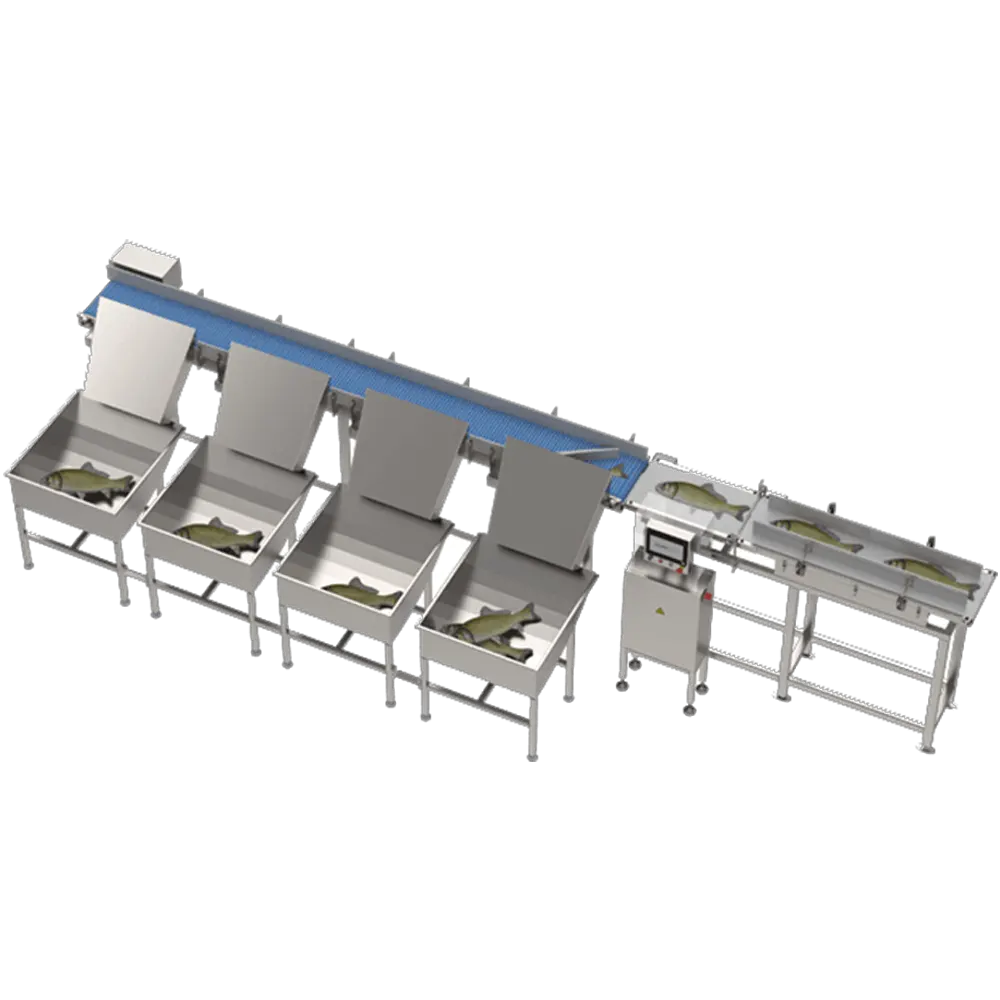

Accurate measurement in fish grading processes is critical for both product quality and production line efficiency. Sensors used to measure fish length and weight provide high precision at the millimeter and gram levels. This precision ensures that each fish is sorted and packaged in full compliance with the length and weight criteria. By minimizing the risk of inaccurate measurements, quality standards are maintained and faulty shipments are prevented in logistics processes.

The system offers a critical advantage, particularly in production lines where fish of varying sizes and weights are mixed. Each fish is detected by sensors, and the grading and weighing process is performed automatically. This minimizes operator intervention, saving labor and ensuring uninterrupted production. Classifying fish to the correct size ensures error-free product flow during packaging and storage.

The accuracy mechanism is designed to operate independently of potential environmental influences on the production line. Factors such as humidity, temperature, and vibration do not affect measurement accuracy. This feature ensures reliable data even under particularly intensive production conditions. Furthermore, the system is supported by continuous calibration and automatic zeroing. This ensures consistent and accurate results, even during long production runs.

Precise and accurate measurement strengthens the quality control process. By analyzing measurement data, operators and managers can quickly identify defective products and optimize production processes. Deviations on the production line are immediately detected, and necessary precautions can be taken. This reduces waste rates and increases production efficiency.

The user interface is crucial for the efficient and error-free operation of the production line in fish processing plants. The 10.2-inch color touch panel allows operators to easily and quickly manage all processes. Weighing data, sizing results, labeling status, and error alerts can be monitored in real-time on the panel. This visual and intuitive interface allows operators to control the device quickly and accurately.

The panel is designed with various menus and icons, ensuring ease of use. Operators can make complex settings with just a few touches, instantly change device parameters, and view detailed production line status. This feature contributes to uninterrupted and error-free workflow, especially in busy production lines.

The color display facilitates analysis by visualizing production data with graphs and tables. Fish length and weight distribution, defective package rates, and production performance trends can be monitored on the panel. This allows quality control teams to quickly identify defective products and take the necessary precautions. Furthermore, historical data storage provides a valuable data source for long-term production planning and analysis.

The touch panel is designed to withstand the challenging conditions of the production environment. Factors such as humidity, water splashes, and vibration do not affect the panel’s performance. This durability ensures long-term and reliable use in fish processing facilities. The panel also functions as an integrated control center, fully compatible with conveyor, weighing, and labeling systems.

The 10.2-inch color touch panel reduces operator workload, minimizes errors, and enables efficient production line management. This allows facilities to increase operational performance and ensure a reliable production process while maintaining production quality.

Accurately recording and analyzing production data in fish grading processes plays a critical role in quality control and operational efficiency. The system records the length and weight measurements of each fish and presents this information statistically, processing it in graphs and tables. This allows for easy monitoring of production line performance, defect rates, and size distribution.

Data visualized through graphs enables operators and managers to make quick decisions. It allows for clear monitoring of which size ranges produce defects more frequently, the performance of specific points on the production line, and production trends. This data enables proactive steps to be taken during quality control and enables the separation of defective packages before shipment.

The system stores all production line data long-term, enabling historical analysis. This allows for optimized production planning, reduced waste, and increased operational efficiency throughout the facility. Furthermore, statistical data helps identify areas for improvement in production processes.

Data visualization reduces operator workload. In complex production lines, all critical information is presented clearly on the dashboard, enabling rapid intervention. Graphs clearly display production trends, making it easier to detect real-time deviations. This ensures continuous and reliable control of the production line.

Statistical data and graphs contribute significantly to the efficient, reliable, and error-free operation of the fish grading machine. They support production line optimization, strengthen quality control processes, and improve operational performance. This feature helps facilities both increase production capacity and ensure product quality.

The uninterrupted and efficient operation of production lines in fish processing plants depends on the rapid and safe replacement of conveyor systems. Easy conveyor replacement allows operators to remove and replace conveyor components with minimal intervention. This allows production lines to run smoothly and workflow continues uninterrupted. This flexibility directly increases production efficiency, especially in lines processing fish of varying sizes and weights.

The system is supported by an automatic calibration feature during conveyor replacement. When a new conveyor is installed, sensors and weighing systems are automatically reset, ensuring accurate measurements. This reduces the risk of inaccurate weighing or sizing, especially in high-volume production processes. Operators only manage the replacement process; the system automatically performs all calibration steps.

Easy conveyor replacement also simplifies maintenance and cleaning processes. The ability to quickly remove and replace components ensures the production line is cleaned in accordance with hygiene standards. This feature offers a significant advantage, as hygiene, quality, and safety are critical in fish processing plants. Furthermore, operator safety is enhanced because system-assisted replacement is performed instead of manually moving heavy or large conveyor components.

This feature also increases the flexibility of the production line. A single device can process fish of varying sizes and weights. Conveyor replacement is quick and easy, allowing for more efficient production planning. Interruptions during the production process are reduced, productivity is increased, and labor is saved.

Easy conveyor replacement is a critical feature in fish processing machines, increasing operational efficiency, reducing error rates, and supporting uninterrupted production line operation. This system improves both quality and safety, reduces operator workload, and increases the plant’s production performance.

In fish processing plants where operators speak different languages, multilingual interface support provides a significant advantage. This feature allows operators to manage the production line in their own language, accurately understand error alerts, and quickly execute operations. Multilingual options reduce the risk of misuse and contribute to the uninterrupted operation of the production process.

The system is designed to present menus, alerts, and settings screens in different languages. Operators can easily switch languages on the device interface and manage operations without interruption. This flexibility is a critical advantage, especially in international production facilities. Multiple language options enhance communication between teams and support error-free operator operation.

Multilingual support also simplifies training processes. New operators can learn the interface in their own language and quickly adapt to the production line. This reduces the risk of errors on production lines and helps operators use the device more effectively. It also enables rapid implementation of the device across different production facilities.

The interface implements language changes in a user-friendly manner. Operators can switch languages at any time and continue to operate the device without interfering with the production process. This feature ensures flexibility and user-friendliness of the production line. All critical information is presented clearly in each language, ensuring error-free operation for operators.

In conclusion, multi-language options combine ease of use, efficiency, and safety in fish grading machines. They reduce operator workload, ensure efficient production lines, and strengthen quality control processes. This technology is a key feature that supports error-free and fast operator operation in modern production facilities.

Maintaining measurement and weighing accuracy in fish grading machines is critical to the safety and efficiency of the production line. The intelligent automatic zeroing system continuously monitors the sensors and weighing mechanisms and automatically zeros them at regular intervals. This prevents deviations on the production line and ensures that every fish is measured accurately.

The system is designed to require minimal operator intervention. As fish arrive at the processing line, sensors instantly monitor the weighing and grading processes and automatically correct any measurement deviations. This significantly reduces the risk of inaccurate measurements, especially under busy production conditions. Operators simply monitor the system and can make fine adjustments as needed, saving labor.

The intelligent automatic zeroing system is also optimized for fish of varying sizes and weights. The sensors detect the length and weight characteristics of each fish and perform the appropriate zeroing according to the system. This feature increases the flexibility of the production line and ensures reliable operation of the device with different fish species. Furthermore, the system enables consistent and accurate data acquisition over long production periods.

This technology also supports quality control processes. The automatic zeroing system, integrated with production data, facilitates the separation of defective packages and increases reliability on the production line. Early detection of errors reduces waste and improves production performance. Furthermore, automatic sensor calibration simplifies maintenance processes and reduces operator workload.

In conclusion, intelligent automatic zeroing is a critical feature that ensures measurement accuracy and production safety in fish grading machines. The system increases operational efficiency, ensures error-free and reliable workflows in the production line, and contributes to maintaining quality standards.