Production processes in the chemical sector are usually based on formulations that require high precision and meticulous supervision. Since the content of the products consists of a mixture of active or auxiliary substances in certain proportions, the weight of each package is critical for the accuracy of production.roduction processes in the chemical sector are usually based on formulations that require high precision and meticulous supervision. Since the content of the products consists of a mixture of active or auxiliary substances in certain proportions, the weight of each package is critical for the accuracy of production. In this direction, the weight control scales used on production lines ensure not only the control of the final product, but also the sustainability of production quality.

Chemical products include products in very different forms and Decencies, such as liquid detergents, industrial cleaning materials, paints and resins, adhesives or laboratory chemicals. This diversity makes it imperative that weighing systems can work with the same precision on a wide range of products.hemical products include products in very different forms and Decencies, such as liquid detergents, industrial cleaning materials, paints and resins, adhesives or laboratory chemicals. This diversity makes it imperative that weighing systems can work with the same precision on a wide range of products. In enterprises with high production volumes, automatic weight control systems eliminate the risk of manual errors and maintain production continuity.

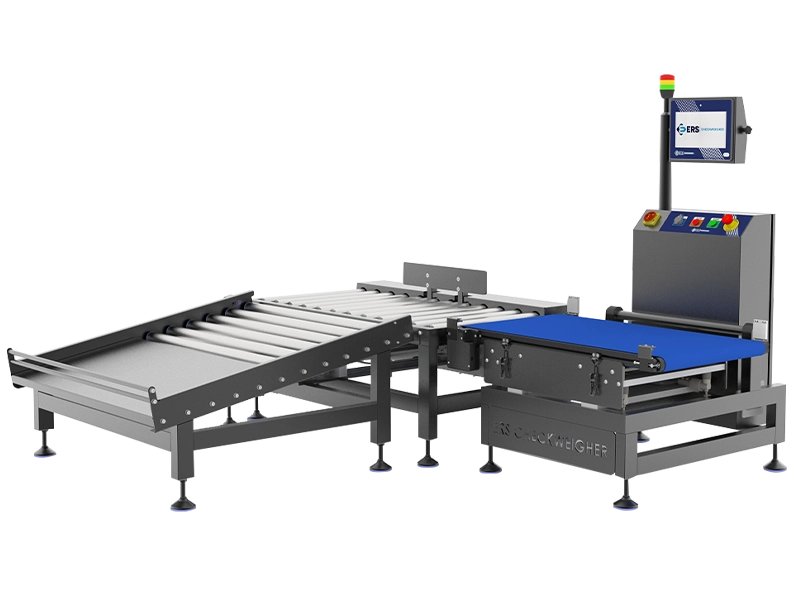

In addition, some products in the chemical industry may contain dangerous or volatile components. For this reason, the control systems used must be resistant to outdoor conditions, sealed and equipped with security measures. Designs that offer the possibility of quick cleaning in case of possible spillage or contamination in production areas are preferred.n addition, some products in the chemical industry may contain dangerous or volatile components. For this reason, the control systems used must be resistant to outdoor conditions, sealed and equipped with security measures. Designs that offer the possibility of quick cleaning in case of possible spillage or contamination in production areas are preferred. Features such as stainless surfaces, high temperature and moisture resistance provide critical advantages for these areas.

Ensuring that products are of the correct weight is not only a legal obligation but also a requirement of customer trust. Poor quality filling or insufficient weight can seriously damage the reliability of the manufacturer’s brand, especially when it comes to chemicals developed for professional usensuring that products are of the correct weight is not only a legal obligation but also a requirement of customer trust. Poor quality filling or insufficient weight

Consumer expectations in the cosmetics industry are not limited to product quality alone; packaging order, grammage consistency and visual integrity also directly affect brand perception. Therefore, weight control scales used in production lines play a critical role in protecting brand value asonsumer expectations in the cosmetics industry are not limited to product quality alone; packaging order, grammage consistency and visual integrity also directly affect brand perception. Therefore, weight control scales used in production lines play a critical role in protecting brand value as well as product quality. Especially in high-volume productions, filling in the correct weight should be provided without errors and automatically.

The variety in cosmetics produced in different forms such as shampoo, cream, lotion, perfume, foundation, lipstick, soap and serum is high. This requires flexibility and product recognition capability from the systemsosmetics produced in different forms such as shampoo, cream, lotion, perfume, foundation, lipstick, soap and serum is high. This requires flexibility and product recognition capability from the systems. The ability to check products of different sizes on the same line provides speehe variety in cosmetics produced in different forms such as shampoo, cream, lotion, perfume, foundation, lipstick, soap and serum is high. This requires flexibility and product recognition capability from the systems. The ability to check products of different sizes on the same line provides speed and cost advantages.

After filling, the product is checked for whether it is at the target weight with milligram precision. Non-standard products are separated and only those with the appropriate weight are packaged. Thus, every product offered to the consumer is the same content and quantity; brand consistency is maintained.

In addition, the sector is strictly subject to regulations. Especially in export, the Decoupling between the weight on the package and the actual content is mandatory. The reporting and traceability features offered by weight control systems provide a great advantage to companies in audits.In addition, the sector is strictly subject to regulations. Especially in export, the Decoupling between the weight on the package and the actual content is mandatory. The reporting an

It provides accurate and precise weighing of chemical products.

It offers the same sensitivity on different types of products.

It is leak-proof, easy to clean and has a durable structure.

It meets the legal requirements and maintains customer trust.