In the construction materials sector, it is critical for the products to be at the right weight, both in terms of performance and safety. The production and packaging of products such as cement bags, iron ties, screws and nuts in the correct weight ensures the creation of trouble-free and durable structures on the site.n the construction materials sector, it is critical for the products to be at the right weight, both in terms of performance and safety. The production and packaging of products such as cement bags, iron ties, screws and nuts in the correct weight ensures the creation of trouble-free and durable structures on the site. Therefore, weight control scales on production lines are one of the basic tools of quality control.

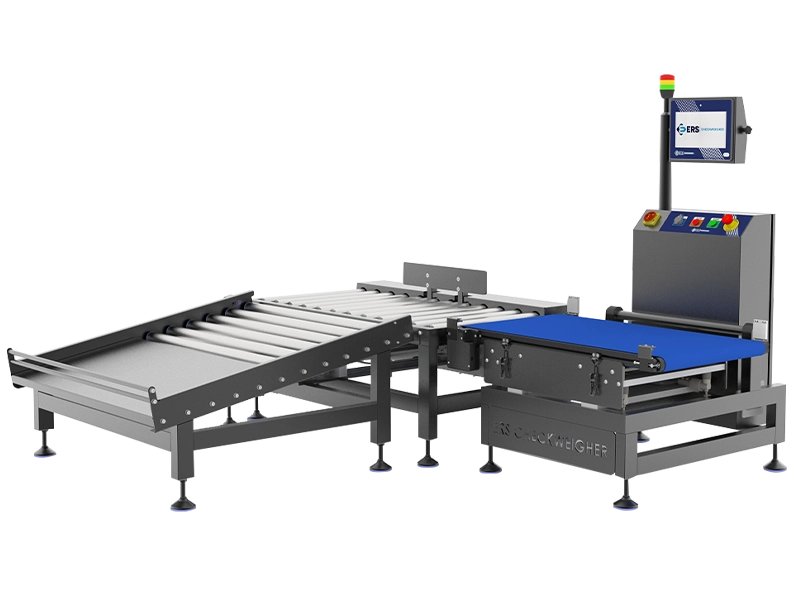

The systems quickly and accurately measure whether the products on the production line are within the specified December. Non-standard products are automatically separated and directed to reprocessing or destruction. This both reduces the rate of waste and guarantees error-free product delivery to the user.he systems quickly and accurately measure whether the products on the production line are within the specified December. Non-standard products are automatically separated and directed to reprocessing or destruction. This both reduces the rate of waste and guarantees error-free product deliver

Accurate weighing is of great importance in the packaging and shipping processes of hardware products in terms of logistics and customer satisfaction. Measuring the net weight of packaged products ensures that transportation plans are made correctly and prevents incorrect loading during shipping.

The weight control scales enable the products in the packaging line to be weighed quickly and accurately. Especially in cases where products of different sizes and weights are used in mixed packages, these systems detect packages containing missing or excess materials. Thus, the error-free product output to the shipment is guaranteed.e weight control scales enable the products in the packaging line to be weighed quickly and accurately. Especially in cases where products of different sizes and weights are used in mixed packages, these systems detect packages containing missing or excess materials. Thus, the error-free product output to the shipment is guaranteed.

The digital recording of weight data facilitates logistics and warehouse management processes. These scales, which work integrated with barcode and ERP systems, offer fast solutions in case of possible errors and complaints by increasing the traceability of the products.

In the hardware sector, control of transportation and storage costs is also optimized with weight control systems. Thanks to accurate weighing, excess transportation costs are reduced and product safety is ensured during shipment.

These systems are adaptable to packaging operations in differentn the hardware sector, control of transportation and storage costs is also optimized with weight control systems. Thanks to accurate weighing, excess transportation costs are reduced and product safety is ensured during shipment.

These systems are adaptable to packaging operations in different sectors. Weighing can be carried out with high accuracy in the packaging lines of different products such as food, medicine, cosmetics, even if the material and package type change. With user-friendly interfaces and easy programmable features, it is possible for operators to provide fast and effective control.

In addition, weight control systems record and analyze critical data related to production quality. Thus, it can be determined at which stage or in which product group errors occur more often. In the light of this information, quality standards can be continuously improved by planning process improvement activities.

Products are weighed quickly and accurately at the target weight.

Packages containing missing or excess materials are detected immediately.

The data is integrated with barcode and ERP systems.

Transportation costs are reduced and product safety is increased.