One of the most critical points of production processes in the food sector is the delivery of products to the consumer in accordance with the standards. Weight control scales come into play at this stage, ensuring compliance with legal regulations and increasing the reliability of brands.ne of the most critical points of production processes in the food sector is the delivery of products to the consumer in accordance with the standards. Weight control scales come into play at this stage, ensuring compliance with legal regulations and increasing the reliability of brands. In particular, preventing weight differences in packaged food production is a factor that directly affects consumer satisfaction. These systems instantly detect missing or overfills by checking the weight of packaged products on the production line with milligram accuracy.

Weight control in modern food production is a safety mechanism that protects not only product quality, but also brand image. Because products released with the wrong weight lead to consumer complaints and can damage the reputation of the company.eight control in modern food production is a safety mechanism that protects not only product quality, but also brand image. Because products released with the wrong weight lead to consumer complaints and can damage the reputation of the company. The precision scales used at this point automatically separate faulty products thanks to the fast separation feature and ensure the shipment of only those that comply with the standards. In addition, it makes the quality control process more transparent by providing instant data to manufacturers with reporting features.

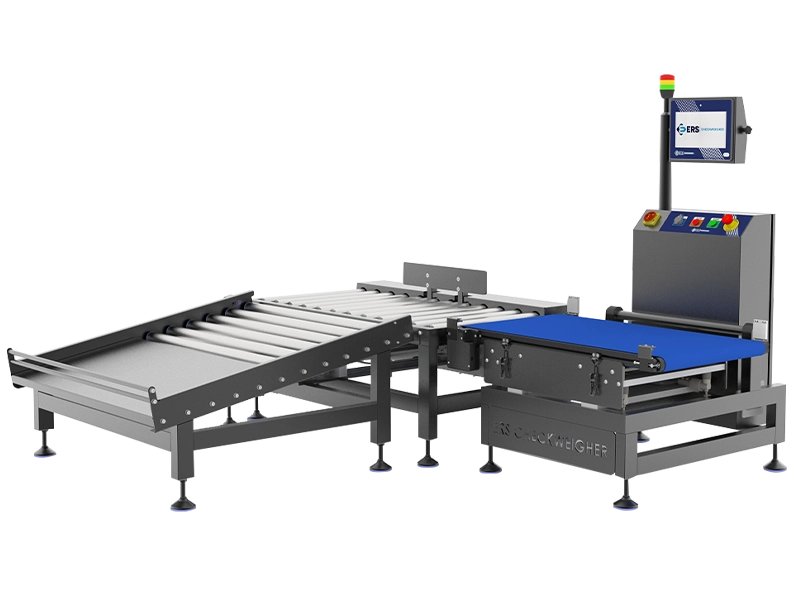

Designed in accordance with hygiene standards, these systems comply with the requirements of the food industry thanks to their stainless steel bodies and easy-to-clean structures. Thus, both food safety is protected during production and the long-term use of the machines is guaranteedesigned in accordance with hygiene standards systems comply with the requirements of the food industry thanks to their stai

The biggest need of companies in the food sector, where competition is intense, is to reduce waste rates to a minimum while increasing production capacity. Weight control scales are activated at this point, providing high efficiency in production lines.he biggest need of companies in the food sector, where competition is intense, is to reduce waste rates to a minimum while increasing production capacity. Weight control scales are activated at this point, providing high efficiency in production lines. Thanks to the correct weighing results, waste of raw materials is prevented, costs are reduced and production processes become more controlled. This situation offers an important advantage, especially for food enterprises engaged in high-volume production.

The integration of technology into production lines has transformed weight control systems from being just quality control devices into a production management tool. Thanks to instant data tracking and digital reporting features, businesses can easily analyze production performanceintegration of technology into lines has transformed weight control systems from being just quality control devices into production management tool. Thanks to instant data tracking and digital reporting features, businesses can easily analyze production performance. In addition, these systems can be integrated into the existing infrastructure by working in harmony with software such as SAP and SCADA. In this way, production processes become more transparent and manageable.

These machines, which stand out with their user-friendly interfaces and touch screens, allow operators to use them quickly and easily. Thanks to its multi-language support, it also offers an ideal solution for companies producing for international marketshese machines, which stand out with their user-friendly interfaces and touch screens, allow operators to use them quickly and easily. Thanks to its multi-language support, it also offers an ideal solution for companies producing for international markets. In addition, thanks to its modular design structure, it can easily adapt to different production lines and capacity increase can be made when necessary.

For food manufacturers, these systems not only provide cost advantages but also help to meet international quality standards. Thus, the competitiveness of companies increases both in the domestic market and in export processes manufacturers, these systems not only provide cost advantages but also help to meet international quality standards. Thus, the competitiveness of companies increases both

Machines are designed in accordance with food safety and according to international hygiene rules.

It provides efficiency in the production line with high speed weighing and control.

MID certified precision delivers results that are spot on, every time.

Safe production processes with special designs that prevent contamination.