In the electronics and IT sectors, even the smallest differences in production processes can directly affect product performance. Therefore, weight control scales are of great importance, especially in the production of sensitive components and devicesn the electronics and IT sectors, even the smallest differences in production processes can directly affect product performance. Therefore, weight control scales are of great importance, especially in the production of sensitive components and devices. These scales detect even micro-level weight differences and guarantee the compliance of products with quality standards.

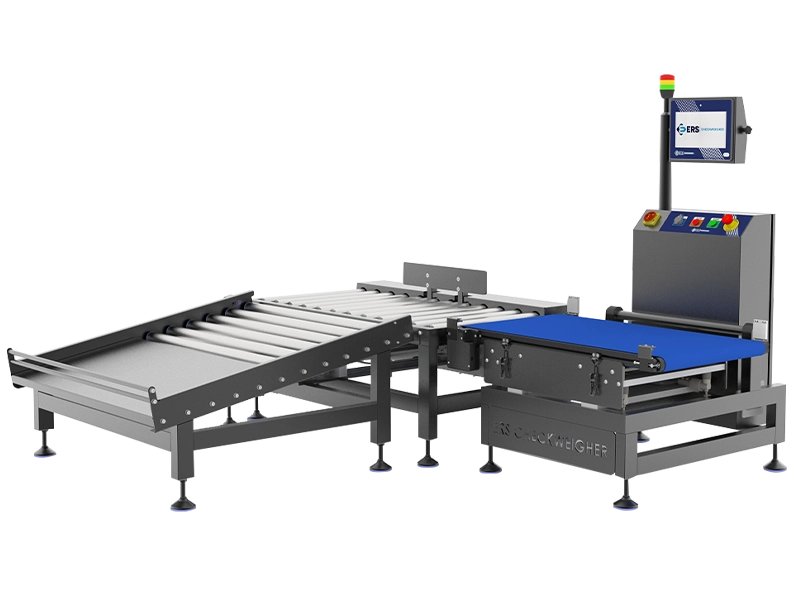

In products such as electronic components, circuit boards, adapters and various accessories, accurate weight measurement is critical not only for quality control, but also for installation and compatibility.n products such as electronic components, circuit boards, adapters and various accessories, accurate weight measurement is critical not only for quality control, but also for installation and compatibility. Weight control systems automatically measure whether each product in the production line is within the target weight December and separate the products outside the limits through the line.

This process increases product reliability and performance, as well as minimizing error rates in the production process. Automatic and fast weighing technologies ensure that the operation continues without interruption even at high production volumeshis process increases product reliability and performance, as well as minimizing error rates in the production process

The packaging and shipping processes of IT products play a critical role in terms of the safety and correct delivery of products. The correct weighing confirms that all the components in the package are contained completely and in accordance with the standards.he packaging and shipping processes of IT products play a critical role in terms of the safety and correct delivery of products. The correct weighing confirms that all the components in the package are contained completely and in accordance with the standards. Weight control scales are used in this process to prevent incorrect packaging and optimize logistics processes.

Weighing systems used in the packaging line allow electronic products of different sizes and weights to be controlled quickly and precisely. In particular, the risk of missing parts in complete system packages or accessory sets is minimized by weight measurementeighing systems used in the packaging line allow electronic products of different sizes and weights to be controlled quickly and precisely. In particular, the risk of missing parts in complete system packages or accessory sets is minimized by weight measurement. Thus, while customer satisfaction is increased, refund and complaint rates are also reduced.

Weight control data is integrated into post-production tracking systems to provide full traceability of the products. In this way, potential problems in the shipping and distribution processes can be detected and intervened in advance. In addition, this data is an important resource in quality reporting and legal compliance

Every electronic part in the package is weighed completely and accurately.

Boxes containing missing or extra parts are automatically eliminated.

Weighing data is recorded digitally and works integrated with tracking systems.

Provides reliable data for quality reports and regulatory audits.