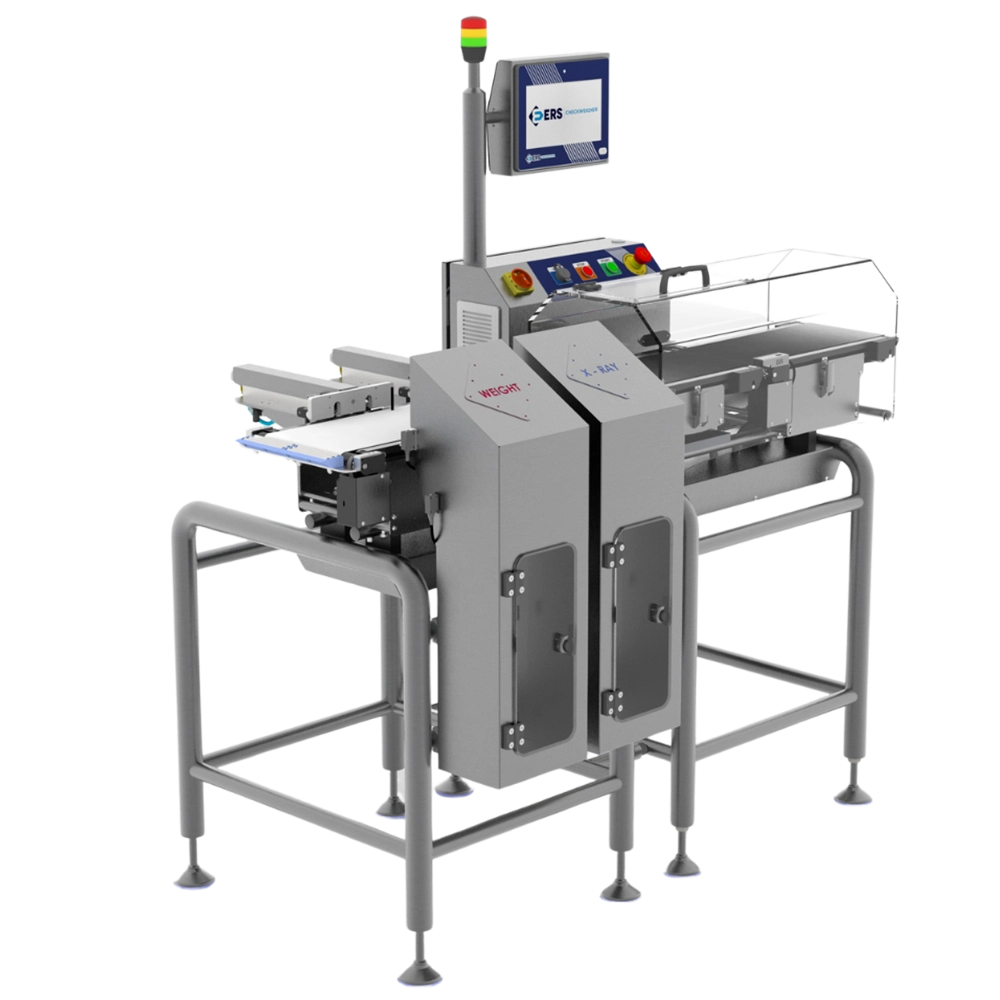

The weight of large capacity boxes can be determined quickly and accurately on the production line, along with the error-free labeling process. The automatic system weighs each box and transmits the correct weight information to the labeling mechanism, preventing faulty packageshe weight of large capacity boxes can be determined quickly and accurately on the production line, along with the error-free labeling process. The automatic system weighs each box and transmits the correct weight information to the labeling mechanism, preventing faulty packages. This feature ensures a seamless and secure workflow on the production line.

The ability to carry out weighing and labeling in large and heavy parcels without the need for human intervention saves both time and labor. The system records the weight data instantaneously and ensures the rapid separation of faulty packages on the production line.he ability to carry out weighing and labeling in large and heavy parcels without the need for human intervention saves both time and labor. The system records the weight data instantaneously and ensures the rapid separation of faulty packages on the production line. Thanks to this, the waste rate decreases and production efficiency increases.

Weighing data enables production managers to analyze. The weight of each parcel is recorded and can be reported in graphs. In this way, deviations in production lines can be easily detected and quality control processes can be carried out more effectivelyeighing data enables production managers to analyze. The weight of each parcel is recorded and can be reported in graphs. In this way, deviations in production lines can be easily detected and quality control processes can be carried out more effectively. Accuracy in the labeling process offers a critical advantage, especially in facilities that comply with international standards.

Accurate labeling of the weight of the boxes also provides convenience in logistics and storage processes. Incorrectly labeled products can lead to both cost losses and logistical confusion. Automatic weight labeling prevents all these problems and guarantees safe, efficient and error-free operation of the production lineate labeling of the weight of the boxes also provides convenience in logistics and storage processes. Incorrectly labeled products can lead to both cost losses and logistical confusion. Automatic weight labeling prevents all these problems and guarantees safe, efficient and err

The reliability of the weighing process in boxes with a capacity of 30,000 g is one of the most critical elements of production quality. The system minimizes deviations by making precise measurements even on the heaviest and largest packageshe reliability of the weighing process in boxes with a capacity of 30,000 g is one of the most critical elements of production quality. The system minimizes deviations by making precise measurements even on the heaviest and largest packages. In this way, each parcel is processed correctly both in terms of weight and content.

Sensor technology is designed to operate without being affected by environmental factors. Factors such as temperature, humidity or vibration do not impair the accuracy of the measurements. Thus, reliable data is obtained continuously on the production line and the decision-making processes of operators are supportedensor technology is designed to operate without being affected by environmental factors. Factors such as temperature, humidity or vibration do not impair the accuracy of the measurements.

Thus, reliable data is obtained continuously on the production line and the decision-making processes of operators are supported. High precision not only ensures the separation of faulty products, but also contributes to the optimization of the production process.

Accuracy is especially important in high-capacity parcels. Large volume packages are more susceptible to weight deviations and manual measurement is prone to errors. The system eliminates these risks with automatic weighing and calibration mechanismsacy is especially important in high-capacity . Large volume packages are more susceptible to weight deviations and manual measurement is prone to errors. The system eliminates these risks with automatic weighing and calibration mechanisms. The weight of the boxes, metal contamination and content compatibility are constantly monitored. Thus, production quality is constantly assured.

Production managers can make process improvements by analyzing sensitive and accurate data obtained from the system. Trends, deviations and performance measurements on the production line are followed up with graphs and reports. This both saves costs and prevents faulty products from entering the market.

As a result, high precision and accuracy directly increase production safety and quality in large capacity boxes. The system ensures error-free production with precise measurements, reduces the workload of operators and maximizes production efficiencys a result, high precision and accuracy directly increase production safety and qualit

The large 10.2-inch display allows all processes on the production line to be easily monitored from a single point. The color touch panel displays weighing and metal scanning data instantly and allows operators to quickly manage all settings.he large 10.2-inch display allows all processes on the production line to be easily monitored from a single point. The color touch panel displays weighing and metal scanning data instantly and allows operators to quickly manage all settings. The interface helps to immediately recognize critical situations thanks to visualized information.

The panel simplifies the use of operators with its intuitive menu design. Settings, calibrations and measurement results are easily accessible on a single screen. In this way, operators ensure uninterrupted operation of the production line by reducing the risk of faultypanel simplifies the use of operators with its intuitive menu design. Settings, calibrations and measurement results are easily accessible on a single screen. In this way, operators ensure uninterrupted operation of the production line by reducing the risk of faulty measurements. In addition, the display maintains its readability even in different lighting conditions and offers ergonomic use in the production environment.

The color touch panel visualizes production data with graphs and tables. This way, operators can easily analyze both current and historical data. Defective products can be detected and separated quickly, and production processes can be optimizedhe color touch panel visualizes production data with graphs and tables. This way, operators can easily analyze both current and historical data. Defective products can be detected and separated quickly, and production processes can be optimized. The graphs clearly show the production performance and faulty product ratios.

The durable design protects the panel from dust, moisture and impacts. This allows the device to be used safely for a long time on busy and demanding production lines. The panel plays a critical role in the management of both weighing and metal detection processes and improves the efficiency of the production line.

As a result, the 10.2-inch color touch panel is an important tool that facilitates control of the production line, increases efficiency and eases the workload of operators. Management of both real-time and historical data supports production safety and quality control processesresult, the 10.2-inch color touch panel is an important tool that facilitates control of th

Detailed analysis of the data collected on the production line is of great importance for quality control and efficiency. The system records the weight and metal scanning data of each parcel and presents this information in understandable graphs and tablesetailed analysis of the data collected on the production line is of great importance for quality control and efficiency. The system records the weight and metal scanning data of each parcel and presents this information in understandable graphs and tables. By following the data in a visualized format, operators can quickly detect faulty parcels and perform the necessary interventions.

The data presented in graphs clearly shows the trends and possible deviations in the production processes. Information such as which shifts produce more defective products or which product types experience more weight deviations can be seen presented in graphs clearly shows the trends and possible deviations in the production processes. Information such as which shifts produce more defective products or which product types experience more weight deviations can be seen clearly. In this way, production planning and quality control processes are managed more effectively. In addition, recording the data creates an important resource for long-term analysis.

Continuous monitoring of production data helps to reduce costs and prevent faulty products from entering the market. By comparing the weights of the parcels and the metal scanning results with the historical data, the performance of the production line can be measured. Thus, it is quickly understood at which points improvement should be made.

Presenting data in graphs and tables accelerates the decision-making processes of operators and managers. Even in complex and large-scale production lines, critical information can be monitored instantly on the screen. This ensures that production lines operate both safely and efficiently.

Statistical data and visualized reports support the control and optimization of production processes. In this way, a faultless, safe and efficient performance is achieved on the production line. Data management stands out as a powerful tool to improve production quality and strengthen operational decisions

The rapid and trouble-free replacement of conveyors during the processing of parcels of different sizes and weights on the production line increases operational flexibility. The system simplifies the removal and installation of parts, minimizing downtime on the production line and reducing the workload of operators.

During conveyor change, the system ensures that each parcel is measured accurately with automatic calibration and adjustment mechanisms. This feature prevents measurement errors, especially in production lines that work with large and heavyuring conveyor change, the system ensures that each parcel is measured accurately with automatic calibration and adjustment mechanisms. This feature prevents measurement errors, especially in production lines that work with large and heavy parcels. Parcels of different weights and sizes are weighed precisely after the conveyor change, and metal screening operations continue smoothly.

Maintenance and cleaning processes are also made easier with conveyor replacement. Quick removal of parts allows cleaning to be done in accordance with hygiene standards. This increases production safety in sensitive production areas such as food, pharmaceuticals and similartenance and cleaning processes are also made easier with conveyor replacement. Quick removal of parts allows cleaning to be done in accordance with hygiene standards. This increases production safety in sensitive production areas such as food, pharmaceuticals and similar. It also reduces occupational safety risks for operators.

Easily interchangeable conveyors increase the flexibility of the production line. A single device can quickly adapt to different product types and saves time in production planningasily interchangeable conveyors increase the flexibility of the production line. A single device can quickly adapt to different product types and saves time in production planning. Operators do not have to pause for a long time during the conveyor change, and the production line continues to operate without interruption.

Conveyor replacement not only provides operator comfort, but also increases production efficiency. The system automatically calibrates itself after changes, guaranteeing accurate measurements. In this way, production processes become more efficient and safe, and the rate of faulty products decreasesr replacement not only provides operator comfort, but also increases production efficiency. The system automatically calibrates itself after changes, guaranteeing accurate measurement

The ability of operators working on the production line to use interfaces in different languages directly affects the effectiveness and safety of the device. Multiple language options allow operators to easily understand menus, warnings and settings in their ownhe ability of operators working on the production line to use interfaces in different languages directly affects the effectiveness and safety of the device. Multiple language options allow operators to easily understand menus, warnings and settings in their own language. This feature makes communication and workflow Decently smooth between employees, especially in multinational production facilities.

Language options increase the intelligibility of the interface, reducing the risk of misuse. Operators can correctly manage the functions of the device and quickly perform operations on the production line. Different language support reduces training time and helps operators to use the device more effectively.

It also provides advantages in terms of multi-language support, production management and quality control processes. Operators can work in their own languages, while managers and quality teams can monitor data in different languages. This strengthens coordination between teams and allows errors to be detected quicklyt also provides advantages in terms of multi-language support, production management and quality control processes. Operators can work in their own languages, while managers and quality teams can monitor data in different languages. This strengthens coordination between teams and allows errors to be detected quickly. The system implements language changes in a user-friendly way and facilitates switching between different language options Decently.

Offering interfaces in different languages also increases the flexibility of the production line. A single device can be used in different production facilities with different language options without any problems. This allows operators to learn the device quickly and increases the efficiency of the production process.

Multiple language options offer ease of use, safety and efficiency in the production line. They contribute to the error-free operation of operators, strengthen the harmony between teams and allow the device to easily adapt to different production environmentsultiple language options offer ease of use, safety and efficiency in the production line. They contribut

The smart automatic reset mechanism plays a critical role in accurately weighing large capacity parcels on the production line. The system automatically resets the sensors at regular intervals and corrects any possible deviationshe smart automatic reset mechanism plays a critical role in accurately weighing large capacity parcels on the production line. The system automatically resets the sensors at regular intervals and corrects any possible deviations. Thus, both weight and metal scanning measurements are carried out continuously with high accuracy.

Automatic reset comes into play without the need for operator intervention, ensuring uninterrupted operation of the production line. Measurement accuracy is maintained even when dealing with large parcels and heavy packages. The system continuously monitors the weighing and scanning processes, ensuring an error-free production process and reducing the waste rate.The reset mechanism works integrated with the production data. Sensor performance and measurement results are constantly monitored, and the system performs its own calibration if necessary.

This increases the reliability of quality control processes and allows for the rapid detection of faulty products in the event of a production defect.he reset mechanism works integrated with the production data. Sensor performance and measurement results are constantly monitored, and the system performs its own calibration if necessary. This inmechanism works integrated with the production data. Sensor performance and measurement results are constantly monitored, and the system performs its own calibration if necessary. This increases the reliability of quality control processes and allows for the rapid detection of faulty products in the event of a production defect.

Automatic reset covers both weighing and metal scanning functions. The system maintains its high performance even under intensive production conditions and accurately analyzes each of the parcels. Operators can manage a safer and more efficient production process by knowing that the device is constantly working correctly.

This mechanism directly contributes to the uninterrupted, safe and efficient operation of the production line. Thanks to intelligent automatic reset, both production quality increases and the workload of operatorsmechanism directly contributes to the uninterrupted, safe and efficient operation of the production line. Thanks to intellig