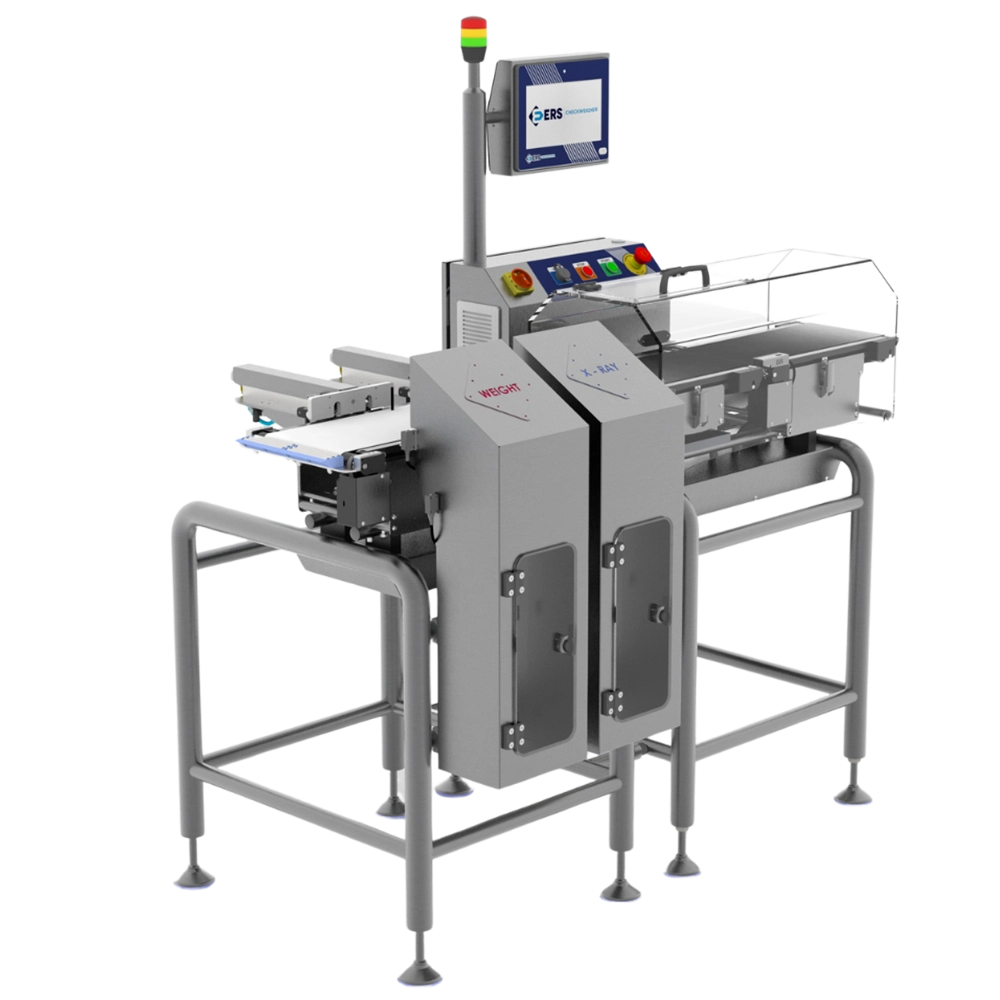

Weight Checking Scale Package Type 1,500 Gr is designed for modern production lines and is equipped with an automatic weight labeling system. This feature ensures that each of the packaged products is of the correct weight and eliminates errors that may occur during manualeight Checking Scale Package Type 1,500 Gr is designed for modern production lines and is equipped with an automatic weight labeling system. This feature ensures that each of the packaged products is of the correct weight and eliminates errors that may occur during manual labeling. Speed and accuracy are of great importance in production processes; automatic labeling helps make the production line both efficient and reliable.

After weighing the products, the device automatically applies the labels according to the determined weight value. Thus, each package complies with both legal standards and customer expectationsfter weighing the products, the device automatically applies the labels according to the determined weight value. Thus, each package complies with both legal standards and customer expectations. Incorrect weighting can lead to both financial losses and customer dissatisfaction, especially in sensitive sectors such as food, chemistry and pharmaceuticals. Thanks to the automatic system, these risks are minimized.

The model, which has a capacity of 1,500 grams, can also process larger packages accurately. This allows for variety in the production line. For example, it is possible to label products of different gramages accurately in flour, pulses or ready-made foodhe model, which has a capacity of 1,500 grams, can also process larger packages accurately. This allows for variety in the production line. For example, it is possible to label products of different gramages accurately in flour, pulses or ready-made food packages. The device measures the weight of each package individually, ensuring that the label is in exactly the right place and carries the right information.

Automatic labeling saves time in the production process. While manual operations require operators to weigh and label individual packages, the device performs this process quickly and accurately. In this way, production speed increases and the workload of operators decreasesutomatic labeling saves time in the production process. While manual operations require operators to weigh and label individual packages, the device performs this process quickly and accurately. In this way, production speed increases and the workload of operators decreases. In addition, the risk of reprocessing or fire due to incorrect labeling is eliminated.

The software of the device can recognize different types of products on the production line and automatically selects the correct labeling mode. This allows the process to run smoothly without the need for user intervention. The production quality is constantly kept high and every package complies with the standards.he software of the device can recognize different types of products on the production line and automatically selects the correct labeling mode. This allows the he software of the device can recognize different types of products on the production line and automatically selects the c

The Weight Control Scale Package Type 1.500 Gr stands out with the superior sensitivity and accuracy features it offers despite its high capacity. Making correct weighing on industrial production lines, especially for products with high weight, is critical both for legal obligations and for customer satisfaction.he Weight Control Scale Package Type 1.500 Gr stands out with the superior sensitivity and accuracy features it offers despite its high capacity. Making correct weighing on industrial production lines, especially for products with high weight, is critical both for legal obligations and for customer satisfaction. Thanks to advanced sensor technology and fast processing capacity, this device weighs each package without errors.

Precision is not limited to measuring only the difference in grams; it directly affects the reliability of the production process. For example, in the packaging of flour, legumes or nuts used in the food industry, a few grams of missing or excess product damages the consumer’s trustision is not limited to measuring only the difference in grams; it directly affects the reliability of the production process.

Precision is not limited to measuring only the difference in grams; it directly affects the reliability of the production process. For example, in the packaging of flour, legumes or nuts used in the food industry, a few grams of missing or excess product damages the consumer’s trustision is not limited to measuring only the difference in grams; it directly affects the reliability of the production process. For example, in the packaging of flour, legumes or nuts used in the food industry, a few grams of missing or excess product damages the consumer’s trust. In sectors such as chemistry or pharmaceuticals, this difference can have much more serious consequences. The package type 1,500 Gr scale eliminates all these risks and guarantees accurate results.

The precision offered by the device is also designed to be compatible with busy production lines. Thanks to its fast data processing feature, it can weigh a large number of packages in seconds and does not compromise accuracy while doing so. Thus, enterprises maintain both the production speed and keep the quality standards constantly high.he precision offered by the device is also designed to be compatible with busy production lines. Thanks to its fast data processing feature, it can weigh a large number of packages in seconds and does not compromise accuracy while doing so. Thus, enterprises maintain both the production speed and keep the quality standards constantly high.

In addition, the device transmits the measurement results to the user instantly. This allows operators to quickly notice possible errors and intervene. Minimizing the deviation rates in measurements contributes to reducing waste rates and reducing costs.

High precision and accuracy make the device not only a weighing tool, but also places it at the center of quality control processes. Thanks to the device, enterprises obtain reliable and standard-compliant products on their production lines.igh precision and accuracy make the device not only a weighing tool, but also places it at the center of quality control processes. Thanks to the device, enterprises obtain reliable and standard-compliant products on their production lines. In the long run, this proigh precision and accuracy make the device not only a weighing tool, but also places it at the center of

Weight Control Scale Package Type 1,500 Gr puts control completely in the hands of the operator in industrial production with its user-friendly 10.2 inch color touch panel. The large screen clearly displays measurement results, setting options and production statisticseight Control Package Type 1,500 Gr puts control completely in the hands of the operator in industrial production with its user-friendly 10.2 inch color touch panel. The large screen clearly displays measurement results, setting options and production statistics. Thanks to the touch interface, menus can be switched between quickly and all functions of the device can be easily managed. In this way, operators can learn the device in a short time and use it without any errors.

The panel serves as the management center of the production process, beyond being just a visual display. Users can monitor weighing results in real time, change measurement intervals or manage automatic zeroing operationsanel serves as the management center of the production process, beyond being just a visual display. Users can monitor weighing results in real time, change measurement intervals or manage automatic zeroing operations.

The graphical and colorful interface facilitates quick decision-making on production lines and makes data reading more intuitive.

Thanks to its durable design, the panel is resistant to dust, moisture and impacts in industrial environments. This feature ensures long-term and reliable use. In addition, the panel’s color display clearly presents the measurement values, especially even in low-light environments.hanks to its durable design, the panel is resistant to dust, moisture and impacts in industrial environments. This feature ensures long-term and reliable use. In addition, the panel’s color display clearly presents the measurement values, especially even in low-light environments. For operators, this is a great advantage in terms of preventing errors and incorrect measurements.

The 10.2-inch touch panel also supports the device’s statistical data and graphics functions. It is possible to visualize production performance, analyze historical data and quickly obtain production reportshe 10.2-inch touch panel also supports the device’s statistical data and graphics functions. It is possible to visualize production performance, analyze historical data and quickly obtain production reports. This provides great convenience not only for operators, but also for managers and quality control teams.

As a result, this color touch panel both improves the user experience and increases efficiency in the production line. The possibility of fast and accurate control maximizes the reliability and functionality of the devices a result, this color touch panel both improves the user experience and increases efficiency in the production line. The possibility of fast

The Weight Control Scale Package Type 1,500 Gr does not only limit the production processes to measurement; it also provides managers and operators with a comprehensive analysis opportunity with statistical data and visual graphs. Each measurement is recorded and can be analyzed retrospectivelyhe Weight Control Scale Package Type 1,500 Gr does not only limit the production processes to measurement; it also provides managers and operators with a comprehensive analysis opportunity with statistical data and visual graphs. Each measurement is recorded and can be analyzed retrospectively. In this way, monitoring of production performance, detection of errors and management of quality control processes become much easier.

The graphics provided by the device visually present performance trends in production lines. For example, it is easy to observe in which shift the rejection rates are high and in which products the weight deviations are greaterhe graphics provided by the device visually present performance trends in production lines. For example, it is easy to observe in which shift the rejection rates are high and in which products the weight deviations are greater. This information helps businesses make more efficient decisions, optimize production processes and reduce costs.

In addition, statistical data also provides significant advantages in the audit and reporting processes. Certifying whether the products comply with the specified weight standards makes it easier to meet the quality and legal standards. In this way, enterprises strengthen both internal quality control and provide a reliable source of data for external audits.

The device’s data recording and graphical reporting functions also provide the opportunity for rapid intervention in the production line. For example, a line deviation or measurement error can be detected and corrected immediately, preventing production losses. This reduces waste and saves labor and timeevice’s data recording and graphical reporting functions also provide the opportunity for rapid intervention in the production line. For example, a line deviation or measurement error can be detected and corrected immediately, preventing production losses. This reduces waste and saves labor and tim

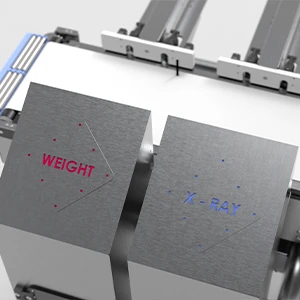

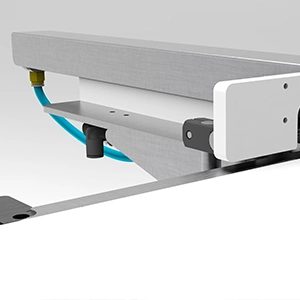

Weight Control Scale Package Type 1,500 Gr has an easy conveyor change feature to process packages of different sizes and types on the same production line. Changing product sizes or weights during production requireseight Control Scale Package Type 1,500 Gr has an easy conveyor change feature to process packages of different sizes and types on the same production line. Changing product sizes or weights during production requires conveyor change. This device prevents the production line from pausing and ensures continuity thanks to the fast and practical conveyor replacement system.

The conveyor change mechanism allows operators to perform the operation with minimum effort. Its design does not require complex settings or special training, which is a great advantage especially in busy production lines. The production line can quickly switch between different package types or sizes and production continues uninterruptedlye conveyor change mechanism allows operators to perform the operation with minimum effort. Its design does not require complex settings or special training,

which is a great advhe conveyor change mechanism allows operators to perform the operation with minimum effort. Its design does not require complex settings or special training, which is a great advantage especially in busy production lines. The production line can quickly switch between different package types or sizes and production continues uninterruptedly.

This feature allows for versatile use of the same line. For example, both small-weight products and large packages of 1,500 grams can be processed quickly through a single line. Thus, enterprises save on the cost of installing additional devices or lines.Oct.

Easy conveyor change also prevents errors. The flexible structure makes it difficult for operators to make incorrect conveyor adjustments and guarantees that products are weighed and labeled correctly. This supports quality control processes and reduces waste ratesconveyor change also prevents errors. The flexible structure makes it difficult for operators to make incorrect conveyor adjustments and guarantees that products are weighed and labeled correctly.

The Weight Control Scale Package Type 1.500 Gr is designed to be used on international production lines with multi-language options. Operators from different countries can use the device’s interface in their own language and manage measurement processes smoothly.he Weight Control Scale Package Type 1.500 Gr is designed to be used on international production lines with multi-language options. Operators from different countries can use the device’s interface in their own language and manage measurement processes smoothly. This feature reduces error rates and increases operator efficiency, especially in multinational production facilities.

Multi-language support also facilitates the training processes of the device. New operators can understand the device in a short time and operate it without errors. This provides high accuracy in production processes while reducing labor costsMulti-language support also facilitates the training processes of the device. New operators can understand the device in a short time and operate it without errors. This provides high accuracy in production processes while reducing labor costs.

In addition, multi-language support provides a great advantage for enterprises that produce export-oriented products. Product labeling, data reporting and quality control processes can be easily managed in different languages. In this way, international standards are maintained and the company’s reliability in global Sundays increases.

As a result, multiple language options make the device usable not only for local use but also on a global scale. It reduces the risk of errors in production processes, increases operator comfort and provides a strategic advantage to the business

Weight Control Scale Package Type 1,500 Gr has an intelligent automatic reset feature that constantly maintains the accuracy of measurements on the production line. Thanks to this system, the device resets itself at regular intervals and minimizes measurement deviationseight Control Scale Package Type 1,500 Gr has an intelligent automatic reset feature that constantly maintains the accuracy of measurements on the production line. Thanks to this system, the device resets itself at regular intervals and minimizes measurement deviations. Thus, there is no need for the operator to intervene constantly.

This feature provides a great advantage, especially in long-term and intensive production lines. Operators do not have to constantly check the sensitivity of the device, production continues uninterruptedly and errors are kept to a minimum. Automatic reset increases the reliability of the device and guarantees that the measurements are always accurateature provides a great advantage, especially in long-term and intensive production lines. Operators do not have to constantly check the sensitivity of the device, production continues uninterruptedly and errors are kept to a minimum. Automatic reset increases the reliability of the device and guarantees that the measurements are always accurate.

This feature also extends the life of the device. Measurement errors are reduced and the sensors are not subjected to unnecessary stress. Operators can manage the production process efficiently and safely.

In conclusion, the smart auto-reset feature not only makes the device a precise weighing tool; it also offers a strategic solution that increases efficiency and reliability in production.