Most of the products produced in the agricultural sector have non-homogeneous sizes and shapes due to their natural structure. Products such as potatoes, onions, tomatoes and apples can come in different sizes, and each packaging process should be carried out with the goal of consistent weight despite this variabilityost of the products produced in the agricultural sector have non-homogeneous sizes and shapes due to their natural structure. Products such as potatoes, onions, tomatoes and apples can come in different sizes, and each packaging process should be carried out with the goal of consistent weight despite this variability. Weight control scales play a critical role in this process, as a precise weighing mechanism is required to meet both the commercial value of the product and consumer expectations.

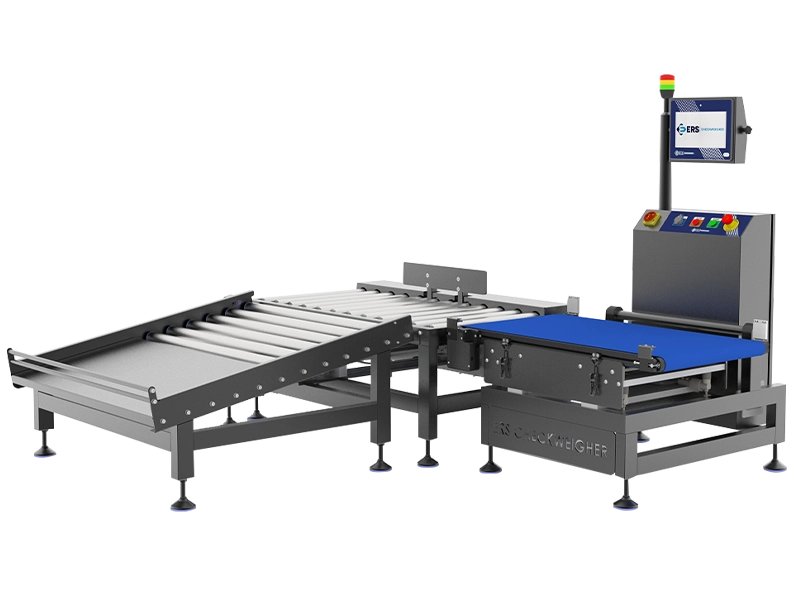

During the processing and packaging of the products from the field, weight control systems integrated into the filling lines automatically inspect each package by weighing it within the specified limits. Products with insufficient or excessive weight are detected and sorted out by the system immediatelyuring the processing and packaging of the products from the field, weight control systems integrated into the filling lines automatically inspect each package by weighing it within the specified limits. Products with insufficient or excessive weight are detected and sorted out by the system immediately. This situation gives the manufacturer the advantage of both reducing waste and selling with the right weight.

Since factors such as seasonality, product density and moisture rate in agricultural products constantly change, it is of great importance for the systems to operate flexibly. The ability of weight control scales to adapt quickly to these variables ensures that production continues without interruptione factors such as seasonality, product density and moisture rate in agricultural products constantly change, it is of great importance for the systems to operate flexibly. The ability of weight control scales to adapt quickly to these variables ensures that production continues without interruption. In addition, the fact that the systems are stainless and dust resistant provides long-term use in soil and humid environments.

In packaging processes, not only the weight of the product but also the total weight of the packaging should be kept under control. Especially for retail sales points, products with predetermined weights are important in terms of consumer trustn packaging processes, not only the weight of the product but also the total weight of the packaging should be kept under control. Especially for retail sales points, products wit

The livestock sector is directly related to the correct dosage and balanced nutrient content in feed production and animal health-oriented production processes. Therefore, the weight control systems used in production facilities are of strategic importance not only for weight control, but also for animal health, cost control and production efficiency.

During feed production, each bag must be filled with the correct ingredients and at the target weight. Weight control scales automate this process, minimizing human error and increasing production speedng feed production, each bag must be filled with the correct ingredients and at the target weight. Weight control scales automate this process, minimizing human error and increasing production speed. It also contributes to the balanced nutrition of animals by ensuring that the ingredients are mixed and packaged in the correct proportions. This is an important factor in terms of health management, especially in large farms and industrial livestock facilities.

Weighing systems used in the livestock sector are expected to be resistant to dusty, dense particulate and variable temperature conditions. Made of stainless steel and easy to clean, these systems offer advantages in terms of both hygiene and longevityeighing systems used in the livestock sector are expected to be resistant to dusty, dense particulate and variable temperature conditions. Made of stainless steel and easy to clean, these systems offer advantages in terms of both hygiene and longevity. Especially the products used in different fields such as milk production, meat processing and feed additives have different weighing sensitivities, which requires modular and adjustable operation of the systems.

In addition, thanks to the digital monitoring and data archiving features offered by weight control systems, manufacturers can record each batch production in detail. In this way, both the quality assurance processes become easier and the traceability of feed contents is increased.n addition, thanks to the digital monitoring and data archiving features offered by weight control systems, manufacturers can record each batch production in detail. In this way, both the quality assurance processes become easier and the traceability of feed contents is increased. Given the increasing regulations in agriculture and animal husbandry, these systems provide companies with an important audit advantage.

Medicated feeds, vitamin supplements or special mixtures that are directly related to animal husbandry also require precise weighing. Thanks to the weight control scales, it is ensured that these products are prepared with the correct dosage, both product safety is increased and animal health is protected.

It provides accurate and precise weighing of chemical products.

It offers the same sensitivity on different types of products.

It is leak-proof, easy to clean and has a durable structure.

Yasal gereklilikleri karşılar ve müşteri güvenini korur.