The fact that the products are in the targeted weight December in the packaging and packaging processes is a critical element both in terms of ensuring customer satisfaction and increasing production efficiency. Weight control scales help to maintain standards in packaging lines by offering automatic and precise measurement at this point.he fact that the products are in the targeted weight December in the packaging and packaging processes is a critical element both in terms of ensuring customer satisfaction and increasing production efficiency. Weight control scales help to maintain standards in packaging lines by offering automatic and precise measurement at this point. Products other than the target weight are separated by the system and production continues without errors and without interruption.

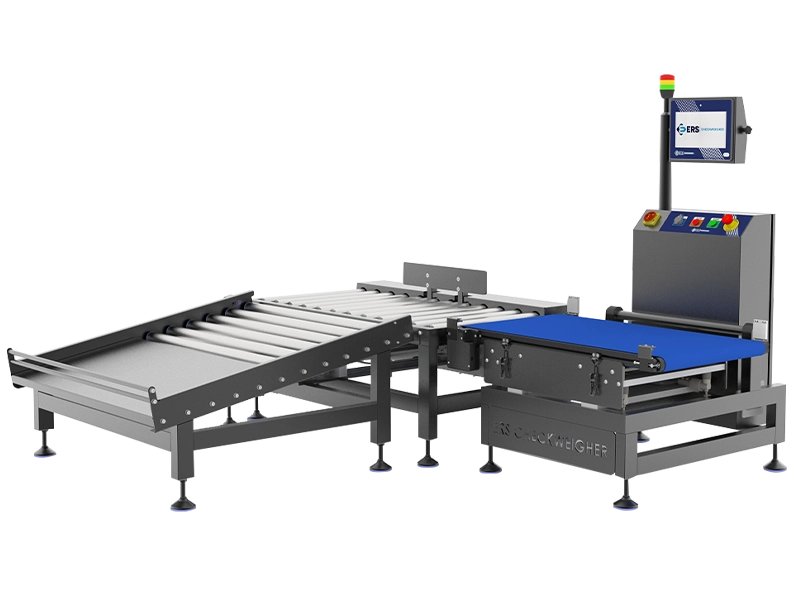

Flexible weight control systems are preferred in modern packaging facilities, which provide the opportunity for rapid adaptation to different product and package types. In this way, products with different weights and packaging formats can be weighed on the same line withoutlexible weight control systems are preferred in modern packaging facilities, which provide the opportunity for rapid adaptation to different product and package types. In this way, products with different weights and packaging formats can be weighed on the same line without any problems. Obtaining accurate and consistent data without reducing production speed and capacity increases the competitiveness of businesses.

Weight data can usually be integrated into production line management systems for real-time control and reporting. This allows reducing waste rates, optimizing inventory control and quality management processes. Automation is especially important in high-volume packaging operations.

Problems such as incomplete filling, excess content or incorrect packaging that may occur in packaging processes both increase production costs and negatively affect customer satisfaction. Weight control scales are sensitive systems designed to prevent these errors.roblems such as incomplete filling, excess content or incorrect packaging that may occur in packaging processes both increase production costs and negatively affect customer satisfaction. Weight control scales are sensitive systems designed to prevent these errors. By checking the net weight of each product in the packaging line at the milligram level, products that are out of tolerance are detected instantly.

These systems are adaptable to packaging operations in different sectors. Highly accurate weighing can be done in packaging lines of different products such as food, pharmaceuticals and cosmetics, even if the material and package type changehese systems are adaptable to packaging operations in different sectors. Highly accurate weighing can be done in packaging lines of different products such as food, pharmaceuticals and cosmetics, even if the material and package type change. With user-friendly interfaces and easy programmable features, it is possible for operators to provide fast and effective control.

In addition, weight control systems record and analyze critical data related to production quality. Thus, it can be determined at which stage or in which product group errors occur more often. In the light of this information, quality standards can be continuously improved by planning process improvement activities.

It minimizes the risk of underfilling or overfilling and faulty packaging.

It can be easily integrated into different lines such as food, pharmaceuticals and cosmetics.

Critical data on production errors is recorded and analyzed.

Errors are reduced, customer satisfaction and efficiency are increased.