Production processes in the pharmaceutical industry are carried out with high precision and strict standards. Producing each tablet, capsule or liquid filling within the specified limits is critical for both patient safety and legal complianceroduction processes in the pharmaceutical industry are carried out with high precision and strict standards. Producing each tablet, capsule or liquid filling within the specified limits is critical for both patient safety and legal compliance. Therefore, the weight control scales used on production lines are not only control equipment; they are also an integral part of pharmaceutical quality assurance systems.

These systems, which offer milligram-level sensitivity, quickly detect incomplete or excessive filling and deviations caused by foreign substances after packaging. Thus, only products that fully comply with the standards come off the production line.hese systems, which offer milligram-level sensitivity, quickly detect incomplete or excessive filling and deviations causThese systems, which offer milligram-level sensitivity, quickly detect incomplete or excessive filling and deviations caused by foreign substances after packaging. Thus, only products that fully comply with the standards come off the production line. These processes are especially mandatory for companies operating within the framework of GMP (Good Production Practices).

The ability to quickly analyze products produced in different formats, such as blister packaging, bottles, cans or injection liquids, prevents pauses in production and ensures the uninterrupted continuation of high-volume production.

In addition, reporting and traceability are of great importance in pharmaceutical production. Automatic data recording and batch-based analysis provided by weight control systems offer convenience in both internal audits and official controls. Since every moment of the process is recorded, deviations can be intervened quickly.

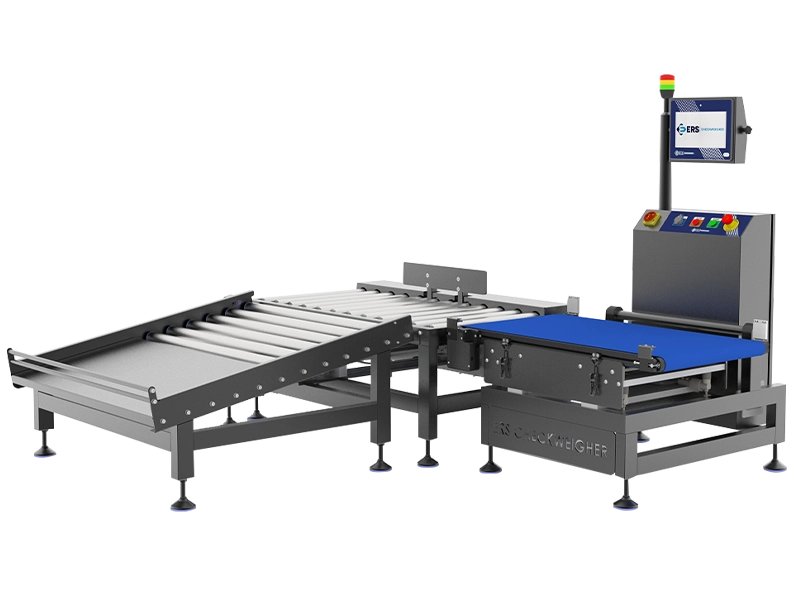

Hygienic design, stainless steel body and easy-to-clean surfaces make the systems suitable for sterile production areas. Thanks to these features, weight check scales not only sort out faulty products; they also support brand reliability and compliance with international regulations

Since the medical sector involves the production of products that directly come into contact with human health, maximum precision and control are essential in the processes. At this point, weight control scales play an important role in the quality assurance chainince the medical sector involves the production of products that directly come into contact with human health, maximum precision and control are essential in the processes. At this point, weight control scales play an important role in the quality assurance chain. Weight-oriented controls become critical in materials such as disposable products, sterile packages, laboratory kits and orthopedic products.

The systems detect the correct amount of packaging while also detecting issues such as ingredient omissions, incorrect assembly or incorrect placement of parts early on. Thus, the shipment of faulty products is prevented and the risk of recalls is reducedThe systems detect the correct amount of packaging while also detecting issues such as ingredient omissions, incorrect assembly or incorrect placement of parts early on. Thus, the shipment of faulty products is prevented and the risk of recalls is reduced.

There is a great variety of products in the medical field and each of them has different sizes and weights. Therefore, the scales need to adapt to different formats on the production line. Thanks to their modular design, the systems can be used in different product types, thus reducing investment costs and simplifying production processes.

The instant tracking of production data and the ability to be archived and analyzed provides a great advantage to companies. Digital data collection facilitates integration into quality management systems and provides a reliable flow of information in audits.The instant tracking of production data and the ability to be archived and analyzed provides a great advantage to companies. Digital data collection facilitates integration into quality management systems and provides a reliable flow of information in audits.

In addition, it is important to produce these systems from ste

Provides micron level accuracy for precise drug weighing.

Solutions in accordance with global norms for the medical sector.

Complete transparency with data integration on the production line.

Safe use with hygienic and easy-to-clean surfaces.