Explore the wide range of products we offer at ERS Checkweigher. Our catalog includes detailed specifications for all our products, from precision weighing systems to advanced control solutions. Browse our catalog to help you choose the most suitable systems to optimize your business processes.

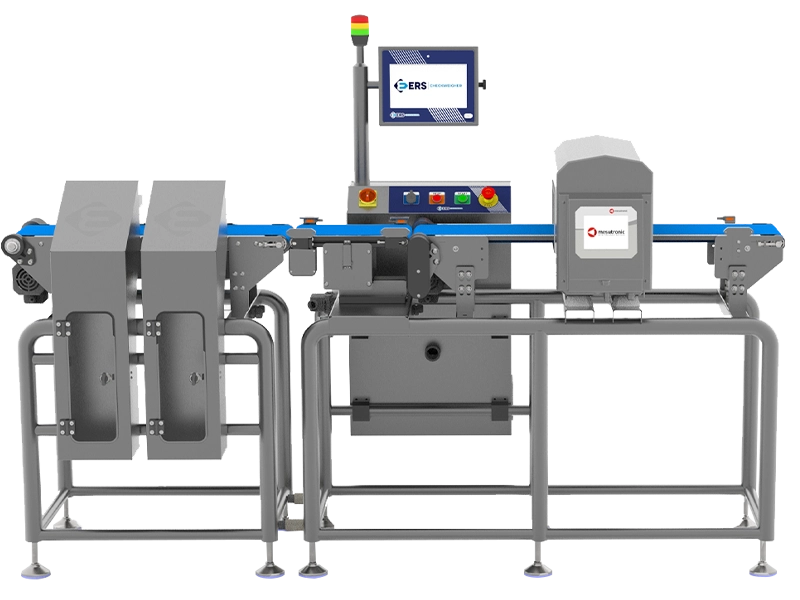

In the food, pharmaceutical, cosmetics, and similar sensitive production sectors, both product safety and weight accuracy are cornerstones of quality management. Combining these two critical control processes, Combined System (Checkweigher + Metal Detector) solutions save space on the production line and combine the functions of two separate devices into a single, compact system. They detect metal contamination and precisely control the weight of each product.

The combined systems offered by ERS Checkweigher are equipped with high-precision sensors and advanced metal detection technologies. The system inspects products moving along the production line for both physical contaminants and weight tolerances, ensuring safe and error-free production. This reduces product losses and maintains customer confidence. This technology, operating through a single system, also contributes to reducing maintenance and operating costs.

With its stainless steel construction, the combined system operates flawlessly in hygienic environments. It is designed to comply with food safety regulations and industry standards. User-friendly displays and reporting systems facilitate rapid operator intervention and increase productivity.

If you want to control both metal contamination and weight deviations in your production line in a single operation, the Combined System (Checkweigher + Metal Detector) is the ideal solution. This system, which simultaneously offers space savings, safety, and quality, has become an indispensable component of modern production lines.

One of the main reasons fish sorting machines are preferred is their high precision in production lines. While manual sorting processes are both time-consuming and error-prone, automatic sorters can determine product dimensions with millimeter accuracy. This eliminates the risk of incorrect sorting and ensures fish classification complies with international quality standards. Furthermore, thanks to their high-speed operation, these machines can process hundreds of fish simultaneously. This increases daily production capacity and significantly reduces labor costs.

The Fish Sorting Machine is designed to be easily integrated into the production flow, especially in facilities with high-speed production. Its stainless steel body and resistance to water and salty environments ensure long-lasting use. These machines, critical to food safety, are used safely in the industry thanks to their easy-to-clean surfaces and hygienic design. Additionally, advanced software systems enable real-time tracking of production data. This allows operators to continuously monitor production processes, generate reports, and make improvements as needed.

ERS Checkweigher is a leading brand in the fish sorting machinery industry for its reliability. The company’s solutions not only sort products quickly and accurately, but also provide businesses with long-term investment advantages. With their durable construction, ease of use, and high-precision technology, ERS Checkweigher’s sorting machines directly contribute to increased efficiency in the fishing industry. These machines increase competitiveness in both national and international markets and maximize customer satisfaction.